How long does a plasma treatment last?

The dependency on the used plasma devices and other influencing factors

Author: Dr. Dariusz Korzec

Date: 2022

First published: ISGATEC JAHRBUCH Dichten. Kleben. Polymer. 2023

The success of plasma treatment on adhesive surfaces depends not only on the treatment itself, but also on how long the treatment lasts. In long production processes, this can lead to surprises that can be avoided by carefully coordinating the pre-treatment with the production processes. This raises the question: how long does a plasma treatment last?

Summary

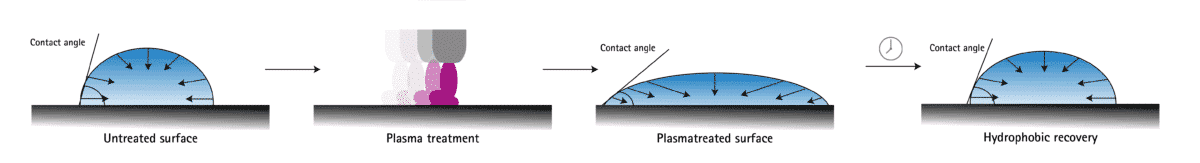

The use of plasma for the pre-treatment of polymers prior to bonding is now an industrial standard. Within a few seconds, the low surface free energy that is characteristic of polymers, often less than 30 mN/m, can be increased to a value of over 60 mN/m. This increases the wettability with liquids and the adhesion of adhesives. In general, the best results are achieved when bonding takes place on a surface immediately after plasma treatment. However, in many cases it is advantageous from a process logistics point of view if bonding is not carried out immediately, but after storage or a longer transport process. Whether such a solution is possible depends on the speed with which the polymer surface loses its high surface energy (also called “hydrophobic recovery”). The following text deals with this effect, its dependence on the plasma devices used and other influencing factors.

Influence of the material

Plasma treatment causes a very strong increase in the free surface energy of polymers. However, this surface energy decreases at different rates in different polymers after plasma treatment. How quickly the activation of the polymers decreases depends on numerous factors. The most important factor is the material used for bonding. Depending on the time of the activation decline, the plastics can be divided into four groups, which are shown in Table 1.

| Hours | Days | Weeks | Months |

|---|---|---|---|

| TPU | PP | LDPE | HDPE |

| PDMS | PCL | SU-8 (Epoxy) | PS |

| PMMA | PBT | PEEK | PC |

| ABS | |||

| PUR | |||

| PES |

In addition to the influence of the material, the following factors also play an important role:

- Influence of the activation method

- Evaluation of the activation decline

- Mechanisms of the decline of activation

- Influence of thermal load

Conclusion – how long does a plasma treatment last?

All polymers show a decrease in activation as a result of storage. This depends primarily on the treated material and the method of plasma generation and can take between hours and months. Activation with nitrogen plasma allows a slower decrease of the activation area by a factor of 15 compared to activation with compressed air. Other important factors that accelerate the decrease of activation are elevated temperature, strong light, strong air movement, mechanical friction and contamination of the ambient air.

When evaluating the decrease in activation, it is important to use a method for determining the activation that is adapted to the process objective, e.g. a contact angle measurement or the determination of the activation area.

You can request the complete article “How long does a plasma treatment last?” as a pdf file here.