Better bonding with atmospheric pressure plasma

Interaction of surface roughness and surface energy with polyethylene

Author: Prof. Dr. rer. nat. Arne Bender, Dipl.-Ing. Sabine Fricke, Alicianne Hocke, B. Sc., – Technische Hochschule Lübeck, Fachbereich MW

Published: 09/2024

First published: Plastic Insights 09/2024

Summary

In the following article, Prof. Dr. Arne Bender and his team from the Technical University of Lübeck examine the interaction of surface roughness and surface energy with polyethylene and how better bonding can be achieved using atmospheric pressure plasma. Among other things, the PiezoBrush PZ3 from relyon plasma was used for surface treatment with atmospheric pressure plasma.

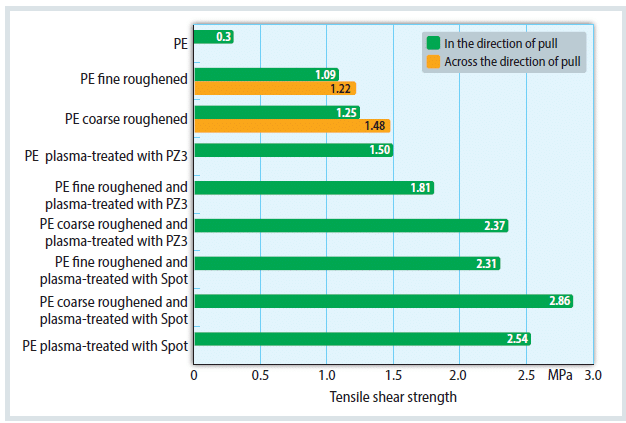

A higher roughness, especially the coarse microscale roughness, ensures higher tensile shear values. Mechanical roughening across the tensile direction provides even higher values. In general, a subsequent plasma treatment leads to even higher values, whereby the T-SPOT with slight substrate heating produces the highest values.

The non-roughened sample plasma-treated with the PiezoBrush PZ3 shows that plasma treatment causes an increase in tensile shear strength. However, prior roughening improves these values, with a coarse microscale roughness providing the best results. The sample that was not roughened and plasma-treated with the T-SPOT illustrates that the higher power of the plasma device causes additional slight melting and an increase in roughness. These are already sufficient to achieve higher tensile shear values than with the finely roughened sample treated with the T-SPOT. However, the best values are achieved with the coarse, microscale roughened sample with subsequent plasma treatment with the T-SPOT.

Conclusion

A coarse microscale roughness is helpful for secure bonding of PE. These tips can better withstand the tensile shear forces and can also be bent slightly during bonding and cause the adhesive and PE surface to catch. The usual parameters must be determined for the roughness and the optimum values must be determined by conducting your own product-specific tests. Roughness can be regarded as a sufficient condition for reliable bonding.

For PE components, it makes sense to determine the surface energy, divided into disperse and polar fractions, by means of contact angle measurements and to modify these values using suitable methods, such as environmentally friendly atmospheric pressure plasma treatment or an adhesion promoter coating, so that they correspond to those of the adhesive. This results in better surface wetting of the adhesive and PE surface and the formation of secondary bonds and thus better adhesion. An increased, coordinated surface energy can be considered a necessary condition for secure bonding. More powerful atmospheric pressure plasma treatments allow not only surface activation but also targeted roughening at the same time. It should be noted that stronger, but not too strong, ion bombardment and a corresponding heat input can create larger but also smoother (coarse microscale) roughness peaks.

The challenge now is to match the roughness (sufficient criterion) and the surface energy (necessary criterion) for the respective materials in such a way that safe and reliable bonds are obtained.

You can download the full article here.