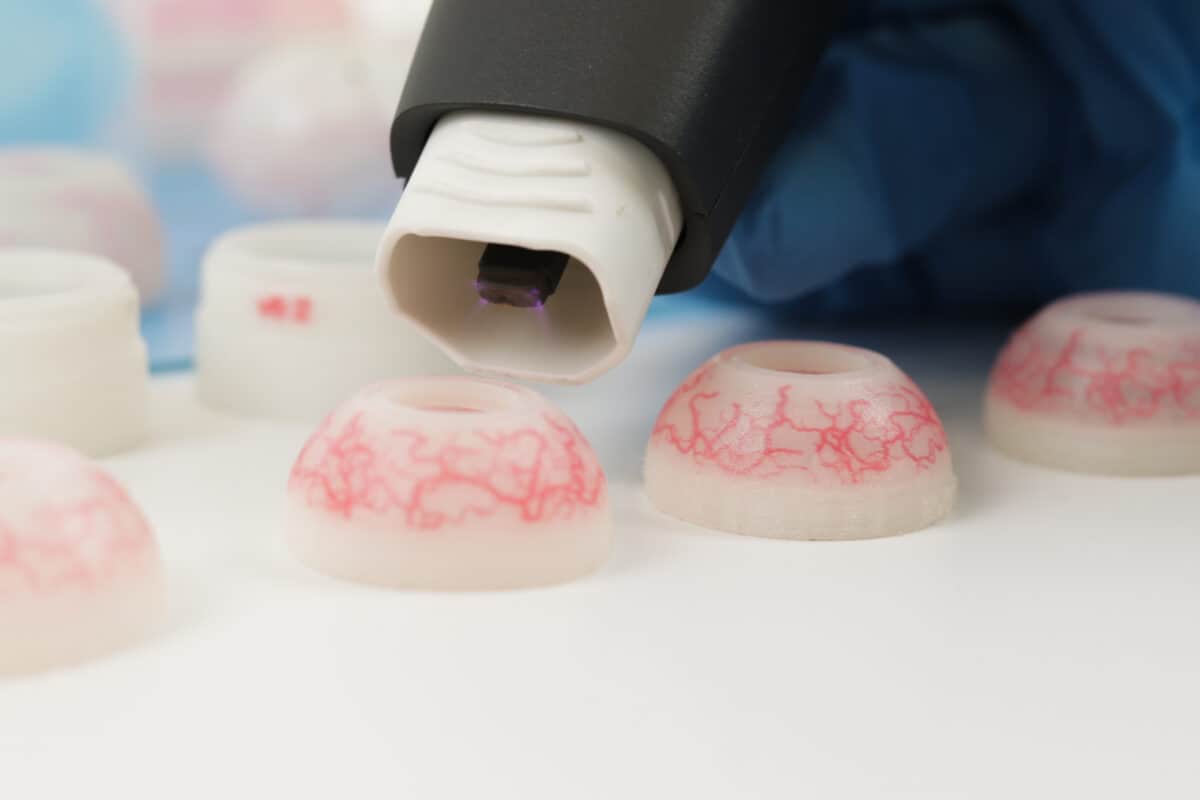

Joining of different plastics for detailed eye models

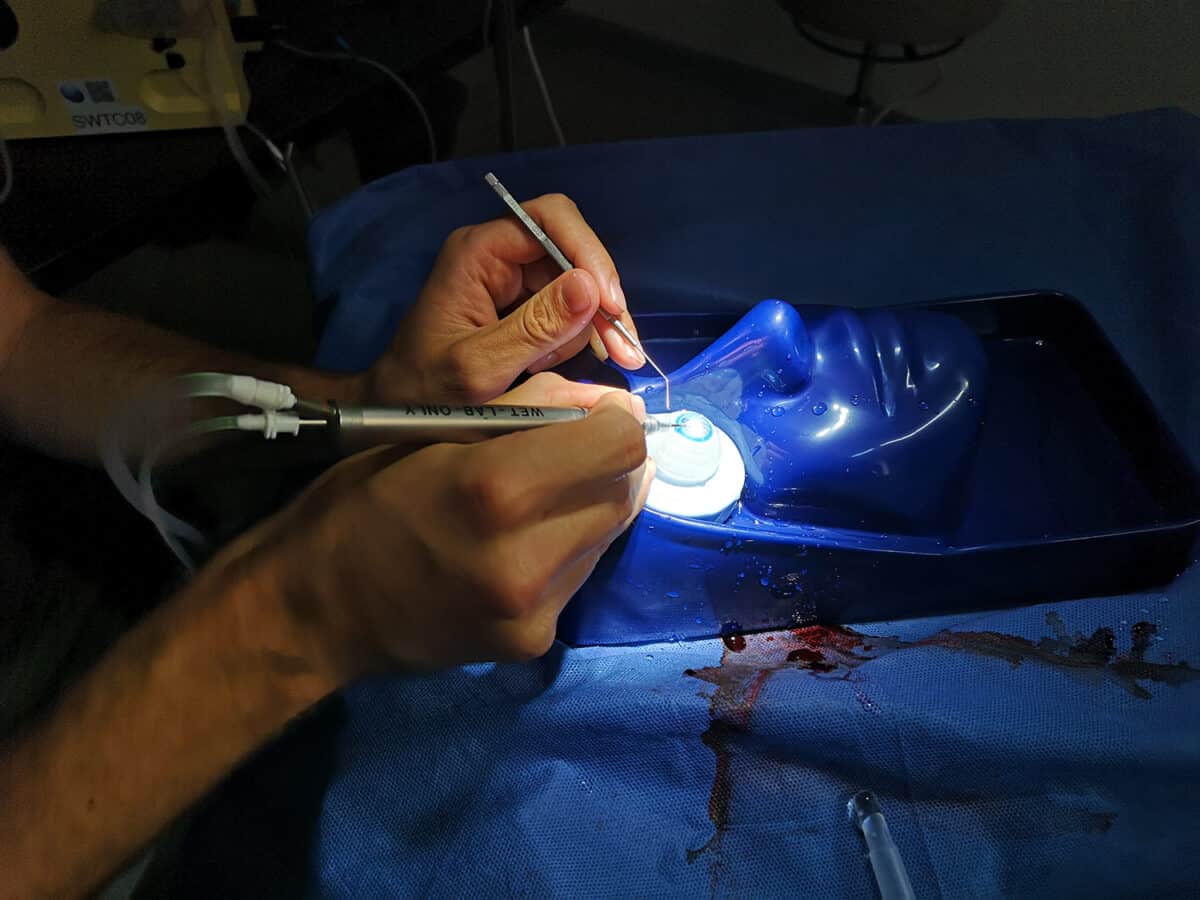

eyecre.at from Ötztal has been producing detailed eye models for surgery training since 2012. The goal is to create an artificial eye that feels like a real one, but has a long shelf life and can be adapted to customer requirements. Therefore, the joining of different plastics is particularly important – at this point, the piezobrush® PZ3 handheld plasma device is used to ensure robustness and high quality.

The best solution was relyon plasma, the world’s smallest handheld plasma device with PDD technology.David Ortner - CEO eyecre.at

Many thanks to relyon plasma GmbH!David Ortner - CEO eyecre.at

About eyecre.at

It all started small, when the CEO, David Ortner, recognized that there was room for improvement after years of experience in doctor training and wetlabs. In a field where the alternatives were limited, he realized it was possible to create a product that could solve most of the existing issues with artificial eye production, while still providing the essential innovations for ophthalmic doctors and companies. Today, Eyecre.at GmbH produces the best solutions available on the market. The market superiority yields from many years of experience in the ophthalmic wetlab equipment sector, and products tailored to customers’ needs, domestically manufactured, and continuously developed.