Dynamic Contact Angle Measuring and Tensiometer (DCAT)

Measuring Imaginary Dynamic Contact Angles on Dental Implants

Author: Dr. Sebastian Schaubach, DataPhysics Instruments GmbH

Date: 05/25/2021

Summary

The tensiometers of the DCAT series with their dedicated software from DataPhysics Instruments are able to determine imaginary contact angles reliably and reproducibly. This is a precious extension of the dynamic contact angle measuring method as it opens up the possibility to easily study hyperhydrophilic materials and, notably, to quantitatively distinguish the results also in cases where conventional methods always yield contact angles of 0°. Researchers in the development of dental implants and other bio-compatible materials will benefit from this feature, just as everybody working in the field of “hyperhydrophilicity” who wants to reliably quantify hydrophilicity differences between very hydorphilic materials.

Introduction

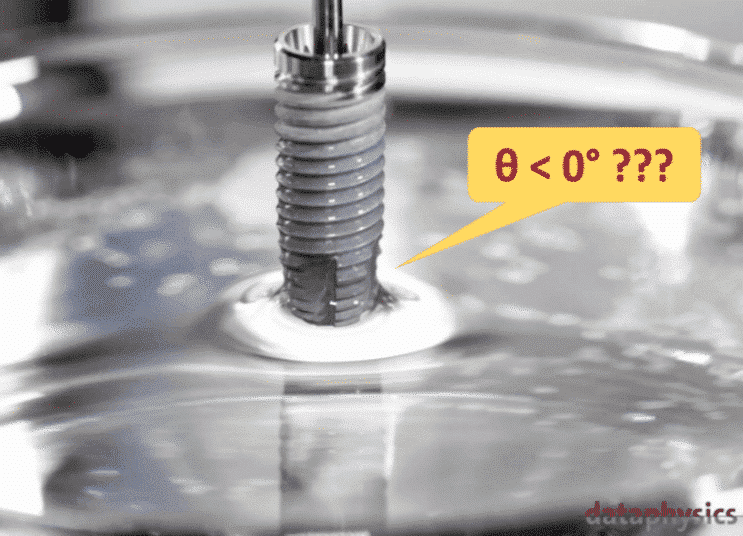

The water contact angle is an important parameter to characterize the wettability of a material and to classify it as hydrophilic or hydrophobic. On materials which are very hydrophilic, water spreads completely over the surface, and a contact angle of 0° is reached. If such very hydrophilic surfaces are sought after, as for example in the development of bio-compatible materials, the question arises if it is possible to distinguish between materials which all possess a 0° water contact angle? How to identify amongst them the one with the very best hydrophilicity? The answer is: this becomes possible with so-called imaginary contact angles. To the best of our knowledge, the DCAT tensiometers from DataPhysics Instruments are the only measuring systems which feature a reliable and reproducible imaginary contact angle determination in their software. In the following the application of the method will be presented at the example of dental implants.

Technique and Method

A tensiometer of the DCAT series from DataPhysics Instruments is a universal measuring system for the force-based study of interfacial parameters and phenomena. With the software module DCATS 32 and suitable sample holders it can be used for dynamic contact angle measuring on various solids, like implants, plates, films, powders, fibre bundles and even single fibres. This is particularly useful for studying hydrophilic samples: When optical contour analysis reaches its limits, one still obtains reliable and accurate results measuring dynamic contact angles with a DCAT thanks to its precise weighing system.

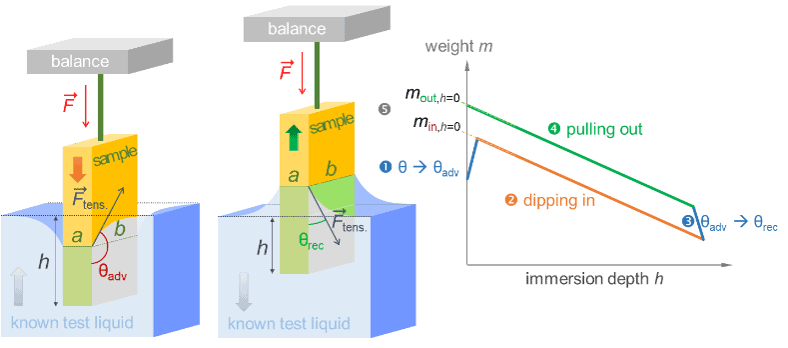

For measuring dynamic contact angles the solid sample is attached to the instrument’s balance via a holder and then dipped into and pulled out off a test liquid with a known surface tension γ (see Fig. 2 left). The measured weight m of the liquid lamella that contacts the sample at the contact line of length L is related to the sought contact angle θ according to the equation

where g is the gravity constant. In order to eliminate the buoyancy effect of the sample the measured weight is extrapolated to zero immersion height h before calculating the advancing contact angle θadv or the receding contact angle θrec for dipping in and pulling out, respectively (cp. Fig. 2 right).

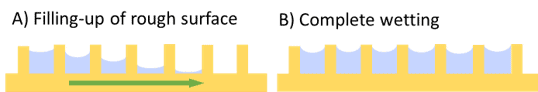

From equation (1), it theoretically should not be bigger than 1 (for which θ is 0°). However, in practice, measurements of very hydrophilic surfaces do yield values of X > 1, in particular for rough surfaces where an additional force is generated during wetting by the capillarity of the porous surface (Fig. 3)

Now, instead of assigning a contact angle of 0° in all those cases, the DataPhysics Instruments tensiometer software calculates the imaginary contact angle, i.e., the complex number fulfilling equation (1). This opens up the possibility to still distinguish between very hydrophilic materials, like the dental implants studied in this application note.

Experiment

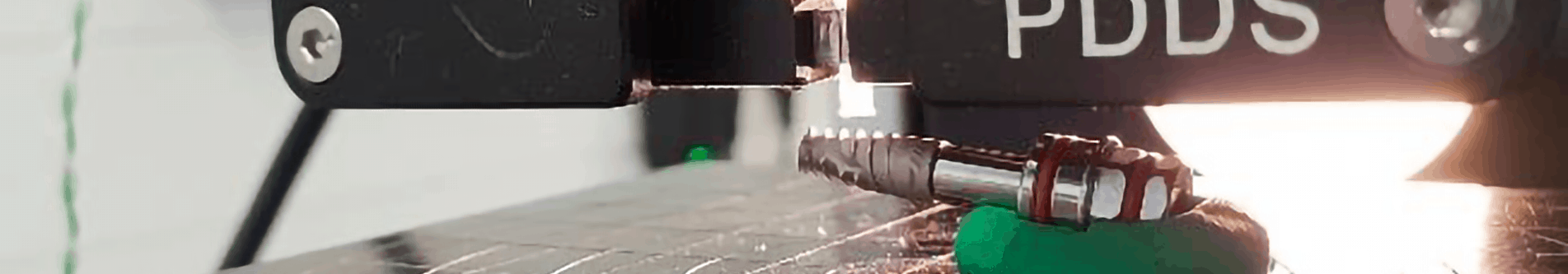

In this application note the advancing and receding contact angles of three different titanium-based dental implants from Nobel Biocare® were determined with a DCAT 25.

Therefore, measurements were carried out on three identical samples per implant, which were taken out of the packaging with as little contact as possible and then analysed without further cleaning or treatment. Afterwards, one of the used samples of implant 3 was plasma treated with the handheld device piezobrush® PZ3 from relyon plasma (metallic: nearfield module) and measured again. Plasma is widely used to increase the hydrophilicity of various materials.

In a preliminary test the surface tension of the water, which was later used as ‘known test liquid’, was measured using a Wilhelmy plate in order to ensure its purity (γ = 72.8 mN/m).

For the dynamic contact angle measuring an implant sample was attached to the sample holder. The method “Dynamic CA” was selected in the software and the sample diameter was typed in (implant 1: 5.5 mm, implant 2: 3.0 mm, implant 3: 4.3 mm). As the implants are slightly tapered, with the tip being a little smaller than the given diameter, the immersion depth was set to 5 mm. Then the measurement was started, and the instrument automatically dipped the sample into the water and pulled it out again, whereafter the software calculated the dynamic contact angles.

Results

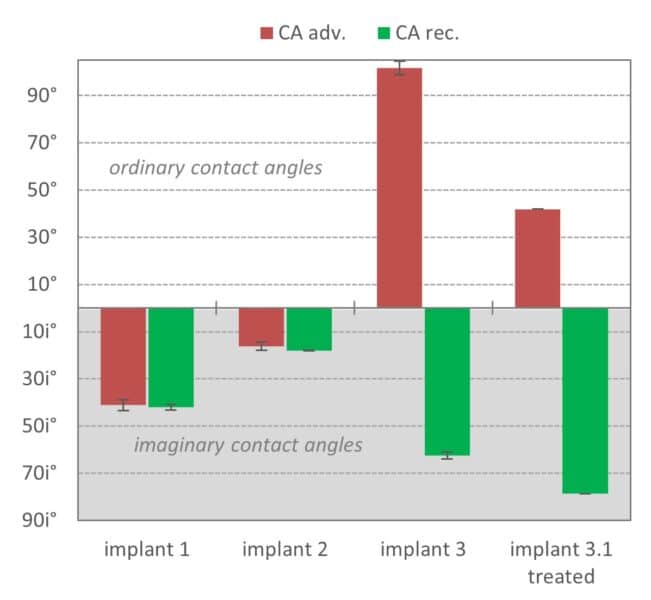

Fig. 4 shows the advancing (red) and the receding (green) contact angles determined for the studied dental implants. For all implants there were only minor deviations between the measurements of the three examined samples, which results in small error bars (± 2.9° max. for CAadv of implant 3).

As can be seen in Fig. 4, both of the advancing CA and receding CA of implant 1 and implant 2 are imaginary values, indicating that these two kinds of surfaces are hyperhydrophilic materials and possess extremely high wetting rates.

Besides, an extremely fast spreading of water on the surfaces was observed during the samples dipping in the water (Fig. 1), which is consistent with the results of CA measurement. Furthermore, implant 1 shows higher imaginary CAs than implant 2, indicating that more extra force at implant 1 was detected during the wetting process caused by extra spreading and capillary forces. Thus Implant 1 is much more hyperhydrophilic than implant 2.

Interestingly, as Fig.4 shown, the advancing CAs of implant 3 are normal CAs with higher than 90o, and around 41o of the CA after the surface was treated with piezobrush® PZ3. This indicates that the wettability of its original surface is not hydrophilic and the wetting rate is extremely low that can be neglect.

Besides, no spreading of water on the surface of implant 3 was observed during dipping in. However, the receding CAs of all samples are the imaginary CAs, which indicates an extra force was detected during the pulling out process caused by the extra spreading and capillary forces. Besides, the CA of the plasma treated implant 3 surface is lower than the untreated surface, indicating that the surfaces has become more hydrophilic after surface treatments.

Therefore, the advancing and receding water contact angles on implant 1 and 2 as well as the receding contact angle on implant 3 are imaginary contact angles. That means conventionally values of 0° would have been obtained in all those cases. The DataPhysics Instruments software, however, determined the imaginary contact angles which permits a further discrimination.