Treatment with atmospheric pressure plasma

Effects of the treatment on the adhesive bonds of metal surfaces

Authores: Öyküm Kanbir, Emel Taşyakan, Kadir Çavdar

Publication: Metal malzeme yüzeylerinin yapıştırma işlemlerinde atmosferik basınçlı plazma uygulamasının etkisi . Gazi Üniversitesi Mühendislik Mimarlık Fakültesi Dergisi, 38 (2), 665-678. DOI: 10.17341/gazimmfd.1025228

First published: https://dergipark.org.tr/tr/pub/gazimmfd/issue/72928/1025228

Summary

The following text summarises the Turkish study on the effect of atmospheric pressure plasma treatment on adhesive bonds of metal surfaces. The plasma treatments were carried out with the piezobrush® PZ2.

Atmospheric pressure plasma (APP) applications have come to the fore in many fields today. They can be applied quickly and stably to material surfaces and offer many advantages over plasma applications in vacuum. With APP, it is possible to improve the surface energies and adhesion behaviour of materials. In this study, the effect of atmospheric pressure plasma application on the adhesive bond strength of galvanised steels (H300LAD) and non-galvanised steels (H300LA) was investigated. Two different materials, two different adhesives and three different plasma application speeds were determined as experimental parameters. The results show that APP application improves the metal bonding process.

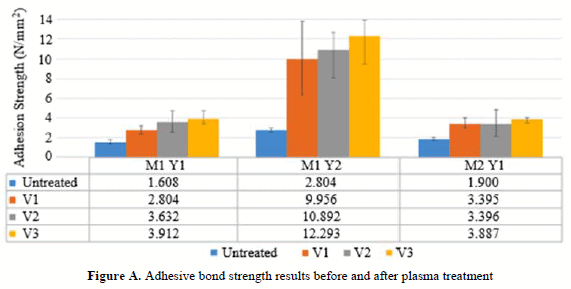

The contact angles of the test specimens made from galvanised and ungalvanised steel material were measured using water drops, and the relative surface tensions were determined using the ink test. These data were compared with those obtained after APP treatment and the effects of plasma treatment on the surface properties were studied. The test specimens produced with different plasma speeds and different adhesives were subjected to a tensile test. The data obtained were used to evaluate the effects of plasma treatment on the adhesive strength of the materials.

After APP treatment, an improvement in surface wettability of approximately 69% was achieved for the galvanised material and 34% for the non-galvanised steel material. In the experimental group (M1 Y2 V3), the adhesion strength increased 4.38 times after APP treatment, with the largest increase. The smallest increase in bond strength was achieved in the experimental group (M1 Y1 V1) with an increase of 1.74 times. While it is clear that bond strength increases with increasing plasma velocity, the most notable increase is the 39% increase in bond strength obtained by changing the velocity from V1 to V3 for galvanised steel.

Conclusion

It was found that the application of APP increases the surface energy of galvanised steel and non-galvanised steel, thereby improving the adhesion behaviour of metals. This difference can be further increased by varying experimental parameters. Furthermore, it was found that the plasma velocity changes the surface energy very effectively.

You can read the full publication in Turkish here.