Fabrication of Elastic and Chemically Inert Gaskets Made of PTFE and PDMS Films

Karlsruhe Institute of Technology (KIT)

Institute of Microstructure Technology (IMT)

A. Voigt, K. Länge, 04/2020

The Case Study of KIT describes the fabrication of elastic and chemically inert gaskets made of PTFE and PDMS films with piezobrush® PZ3

Elastic and chemically highly inert flat gasket sheets are to be developed. For this, PTFE film of 50 μm thickness with a soft acrylic adhesive on one side is to be glued to a soft (40 Shore A) PDMS film with a thickness of 1 mm. As both materials have very low surface energies, it is hard to find an adhesive which bonds those materials together in a stable manner and is also elastic enough to keep the overall elasticity of the gasket.

Preliminary bonding experiments using double-sided adhesive tape

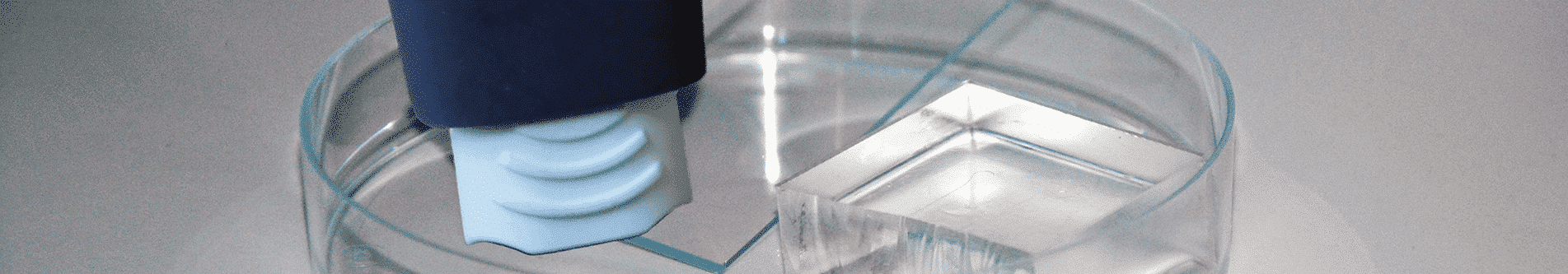

Preliminary tests used double-sided adhesive tape (3MTM High Performance Double Coated Tape 9088-200) to bond the PTFE film and the PDMS film together (Fig. 1).

First tests failed, because the double-sided adhesive tape did not adhere well to the PDMS film. Using a primer based on heptane and a thin film of cyanoacrylate glue on the PDMS led to a surface with a higher energy; and the adhesion of the double-sided adhesive tape was improved. However, the flexibility of the gasket was reduced because of the stiffness of the cyanoacrylate glue.

Bonding experiments with the piezobrush® PZ3 device

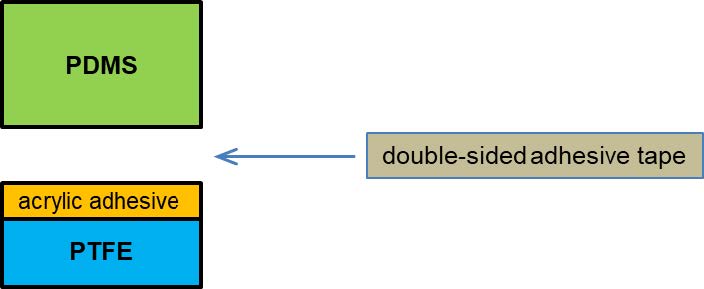

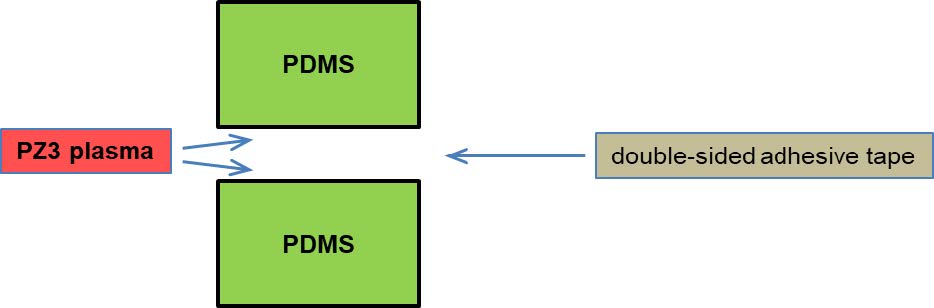

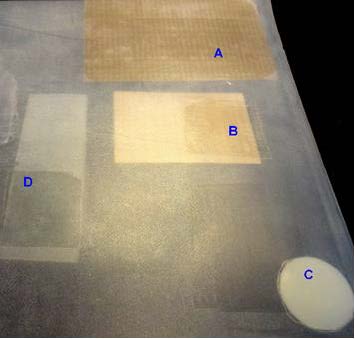

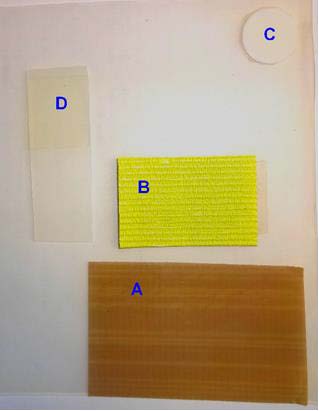

First, the PDMS film surface was treated with piezobrush® PZ3 plasma (1 min at 100% power); and the PTFE film was subsequently bonded with its soft acrylic adhesive side (Fig. 2, Fig. 5 sample A). The adhesion between the films was very good and not affected by deformation of the gasket, i.e., the elastic properties were also maintained. Hence, using double-sided adhesive tape or cyanoacrylate as intermediate layer is no longer required.

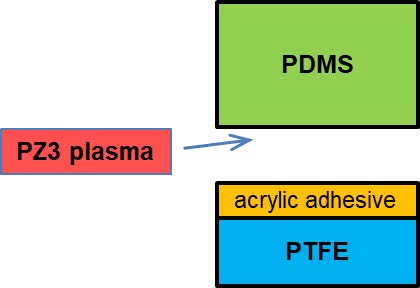

In a second experiment, both PDMS and pure PTFE surfaces were treated with piezobrush® PZ3 plasma and subsequently bonded by means of double-sided adhesive tape (Fig. 3, Fig. 5 samples B and C). This also worked well, provided the force to peel the films apart is not too strong. A similar approach using cyanoacrylate instead of the adhesive tape failed, as the plasma treatment did not improve the adhesion properties of this glue.

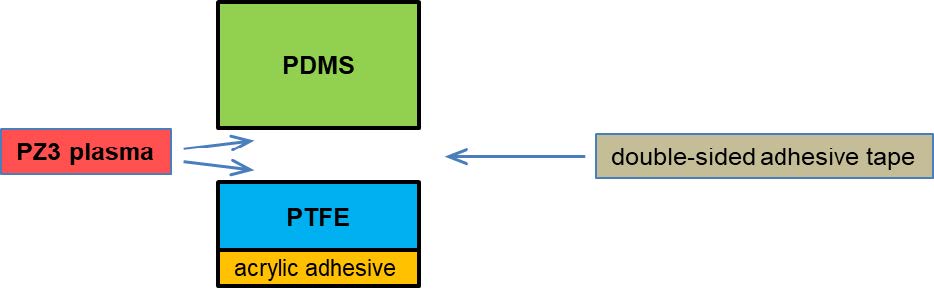

Finally, two PDMS films were surface treated with the piezobrush® PZ3 plasma and subsequently bonded with double-sided adhesive tape (Fig. 4, Fig. 5 samples D). Again, very good adhesion of the bonded films was obtained.

Conclusion

It is commonly known that plasma treatment leads to surface activation resulting in better wetting and adhesive properties. The piezobrush® PZ3 device led to excellent results and is still easy and effortless to handle. Piezobrush® PZ3 plasma treatment of low energy surfaces, such as PDMS and PTFE, allowed subsequent bonding with simple double-sided adhesive tape with only little effort; and the resulting gaskets met the requirements regarding elasticity and chemical inertness.