Contact angle

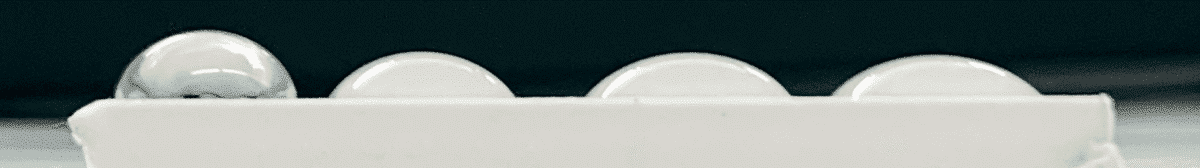

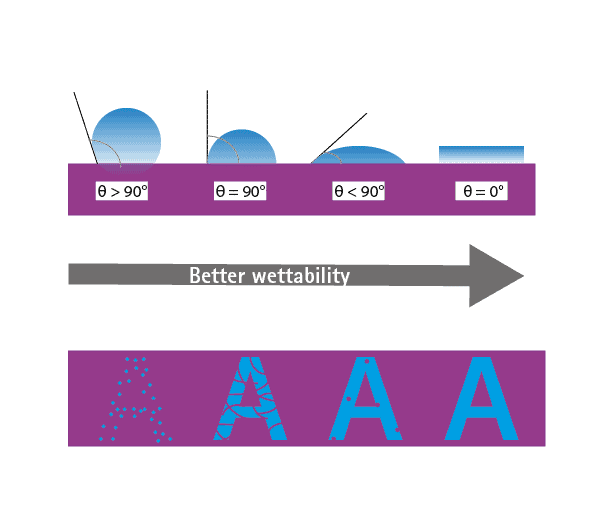

The contact angle is the angle that the surface of a drop of liquid forms with the surface of a solid, whereby the volume of the drop filled with liquid is included in the contact angle. The contact angle is therefore an indicator for checking whether a surface is hydrophilic or hydrophobic (water-repellent). The water contact angle is an important parameter for characterizing the wettability of a material and classifying it as hydrophilic or hydrophobic. On materials that are very hydrophilic, water spreads completely over the surface and a contact angle of 0° is achieved.

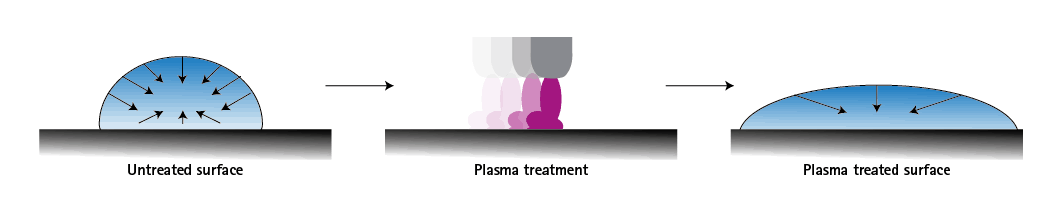

For many processes such as bonding, printing or coating, a hydrophilic surface is required so that the adhesive, ink or coating is optimally distributed on the surface. However, many materials are hydrophobic. This is where plasma treatment comes into play. Prior plasma treatment can make hydrophobic surfaces hydrophilic and thus optimally prepared for downstream processes.

Example of use in the field of printing

The illustration shows the interaction of surface energy, printing ink and plasma. The top image shows a drop of ink applied to a surface and the resulting print below. The first drop has a very large contact angle of over 90° and therefore wets the surface very poorly, causing the ink to contract on the surface and not wet evenly. The two drops in the middle already have a flatter contact angle, which improves the print result. The best result is achieved when the contact angle is 0°, as the ink drops then wet the surface well and an even print image is created.

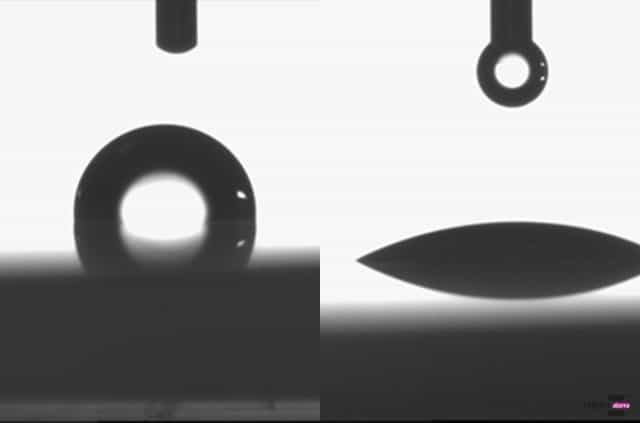

How can the contact angle be measured?

So-called contact angle measuring devices (e.g. from https://www.kruss-scientific.com/ ) are used to quantify these variables simply and reliably. Two test liquids (e.g. water and diiodomethane) are used, drops of which are applied to the surface to be tested. The surface energy of the substrate can be determined with high accuracy from the measured contact angles.