Piezoelectric direct discharge plasma

Piezoelectric direct discharge (PDD) plasma is a type of cold non-equilibrium plasma generated by a direct gas discharge from a high-voltage piezoelectric transformer. It can be ignited in air or other gases in a wide pressure range, including atmospheric pressure. The compactness and efficiency of the piezoelectric transformer make this method of plasma generation particularly compact, efficient, and cost-effective. It enables a wide range of industrial, medical and consumer applications.

Background

Cold, non-equilibrium atmospheric pressure plasmas can be generated by high-voltage discharges in the atmosphere of various working gases. The following three types of electrical discharges have the most applications in industrial processes:

- Arc discharges are self-sustaining DC discharges characterized by high electric currents drawn from the cathode by intense heat and field emission. Due to the intense currents, the volume of the arc reaches thermal equilibrium with temperatures of 6,000 – 12,000 C. While arc discharge can be sustained in DC mode, pulsed operation is more stable against the material defects in a rapidly eroding cathode surface.

- Corona discharges occur in the areas of high electric fields with high field gradients, located near sharp edges of high voltage electrodes. To avoid sparking, such electrodes should be located far from electrical ground. While corona discharges require relatively high voltages, the electrical currents emitted are low, resulting in low discharge power. Although DC operation is standard for corona discharge, AC operation increases its performance.

- Dielectric barrier discharge occurs between two electrodes separated by a dielectric when the electrodes are driven by a sine wave or pulsed high voltage. The discharge current is drawn from the surface of the dielectric. The power of dielectric barrier discharge is much higher than that of corona discharge, but smaller than that of arc discharge.

All these types of electrical discharges require high voltage electronics and high voltage wiring. These are bulky, expensive, and in the case of AC, performance can be very inefficient due to dielectric losses. In addition, industrial applications often require high power of 1 kW. This places high safety requirements on the high voltage open electrode enclosures. A design based on multiple low-voltage high-voltage modules could improve the safety aspects. Similarly, integrating the high-voltage generator and the discharging electrode into a single module should reduce dielectric losses in the cables. However, no cost-effective solution for the system based on low-power modules has been found so far.

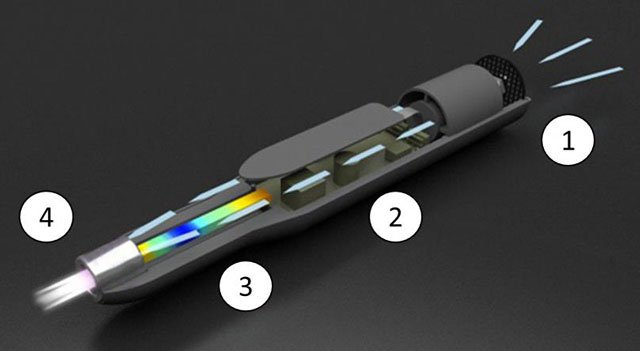

The principle of Piezoelectric Direct Discharge plasma

Piezoelectric direct discharge uses a piezoelectric transformer as a generator of AC high voltage. The high voltage side of this transformer acts as an electrode, causing electrical discharges in the air or other working gases, which in turn generates atmospheric pressure plasmas. The piezoelectric transformer is very compact and requires only one source of low voltage, low power. This allows the entire plasma generator to be built in a particularly compact and cost-effective manner, enabling the construction of hand-held and/or low-cost plasma generators.

Rosen-type piezoelectric transformers, which can be made of lead zirconate titanate, convert electrical energy in the form of low-voltage alternating current into mechanical vibrations. Consequently, these mechanical oscillations generate high voltage AC current at the other end of the transformer. The highest amplitude is achieved at mechanical resonances, which occur at typical frequencies between 10 kHz and 500 kHz. The dimensions of the piezoelectric crystal define the resonant frequency, while its dielectric environment can cause small shifts in resonance. The low-voltage electronics continuously adjust the frequency to keep the transformer operating within resonance. In resonance, such transformers provide very high voltage conversion factors up to 1000 at voltages of 5 – 15 kV.

Properties

Electrical discharges generated in the gas from the high voltage side of the piezoelectric transformer have characteristics that are also found in the corona discharges and in the dielectric barrier discharges. While the first mode occurs when the high voltage side of the piezoelectric transformer is operated far from the electrical ground, the second mode occurs when it is operated near the electrical ground separated by a dielectric. In the vicinity of the open electrical ground, the piezoelectric transformer generates periodic sparks, so-called streamers. The transition to arcing does not occur because the power of the transformer is limited. The typical power of such transformers is in the order of 10 W. The efficiency of plasma generation reaches 90%, while the remaining 10% of power is lost due to mechanical heating of the piezoelectric transformer.

Due to the low electric currents typical of dielectric barrier and corona discharges, piezoelectric direct discharge generates a non-equilibrium plasma. This means that its constituent electrons, ions and the neutral gas particles have different kinetic energy distributions. The temperature of the neutral gas in the plasma volume remains below 50 C. At the same time, the electrons and ions reach energies of 1 – 10 eV. This is 300 – 3000 times higher than the average energy of the neutral gas particles. The densities of the electrons and the ions reach 10-16 – 10-14 m-3. Since most of the plasma volume consists of the cold neutral gas, the plasma is cold. However, the very energetic electrons and ions excite atoms and molecules producing large amounts of short-lived chemical species, which makes this plasma chemically very active.

Applications

The properties of piezoelectric direct discharge plasmas allow a wide range of applications in medical technology, microbiology, and clinical research. Typical industrial applications include ultra-fine cleaning and plasma activation of metal, ceramic, glass, and plastic surfaces. This plasma treatment increases surface energy and improves surface wettability and adhesion. The latter increases the quality of subsequent printing or bonding.

The very compact dimensions of the PDD plasma generator extend the range of applications to include compact devices for laboratory work, hand-held applications, ozone generators and even consumer products.

Learn about our products >>