Wetting behavior during printing

The rapidly growing variety of printable materials brings new opportunities for the printing industry, but also additional challenges. To achieve good wetting and thus a high-quality print result, there are three crucial factors to consider: the material itself, the ink used, and the method of the printing process. These three factors in turn have many relevant properties that influence the wetting behavior during printing.

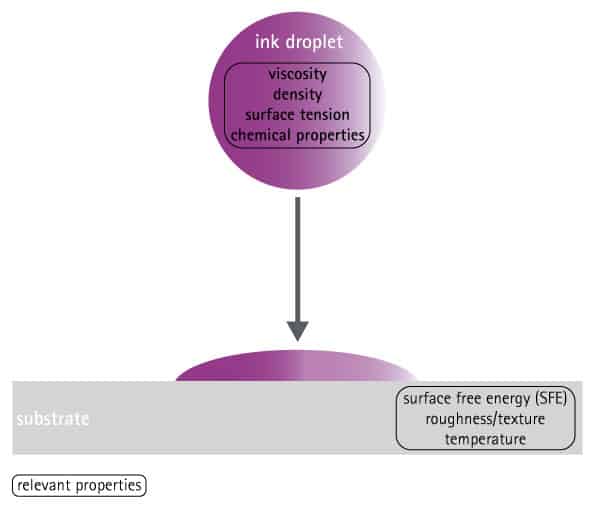

When selecting the material to be printed, for example, the surface free energy, the roughness or texture of the substrate and the temperature sensitivity exert an influence on the wetting behavior.

But the viscosity of the ink, its density, its surface tension, and chemical properties also influence wetting.

This shows that specialization on one of the three factors leads to more specific solutions for niche applications. In addition, a very large number of properties must be considered.

To enable broader compatibility of inks and materials, various pretreatments can be applied. Binders, primers, or other strongly oxidative wet chemicals can be replaced by a plasma treatment of the substrate. This method leads to better wetting behavior of the printing ink on the material to be printed.