How hot is Plasma? Hot Melts and Temperature – Critical Applications

The high temperatures which are reached in most plasma applications make many users wonder about process safety, especially when highly sensitive materials are treated. This article addresses open questions concerning temperature and heat conduction during plasma applications and cites critical examples which substantiate the suitability of plasma for temperature-critical processes. The underlying question is seemingly simple, yet not easy to answer: how hot is plasma?

How hot is plasma?

Naturally occurring plasmas can reach temperatures of up to 106eV (1eV ~ 11600K) [1], in industrial ap-plications maximum temperatures lie around 1eV [2]. Plasmas are therefore a high-energy state, with their temperatures resulting from the energies of their species (neutral atoms, electrons and ions) and depending strongly on the respective plasma’s degree of ionization. This makes it possible to classify different plasmas according to their temperature, distinguishing between two main categories: thermal and non-thermal plasmas.

We speak of thermal plasma when it is fully ionized and all species have the same temperature, classic examples being the sun’s corona or fusion plasma. [3] For this article, the category of non-thermal or non-equilibrium plasmas is relevant. These plasmas have differently tempered electrons, neutral particles and ions. Thus, the electrons may reach temperatures of 10000 K, whereas most gas particles become significantly less hot or remain at room temperature. Yet, a static measurement of the plasma flame generated by plasmabrush® PB3 would yield temperatures below 1000°C during operation with dry compressed air as plasma gas. This plasma flame, the visible foremost part of the plasma jet, is also called “remote plasma“ and is normally the area of the plasma where substrate surfaces are treated.

Non-thermal plasma is often called “cold plasma“; this term should be used carefully as it includes a wide range of low-pressure and atmospheric pressure plasmas. The temperature of the “cold plasma“ generated by piezobrush® PZ2, for example, barely rises above surrounding temperatures, contrary to the heat produced by plasmabrush PB3. This article however focuses on the kind of devices used for high production rates in the industries, which operate with non-thermal high temperature plasmas.

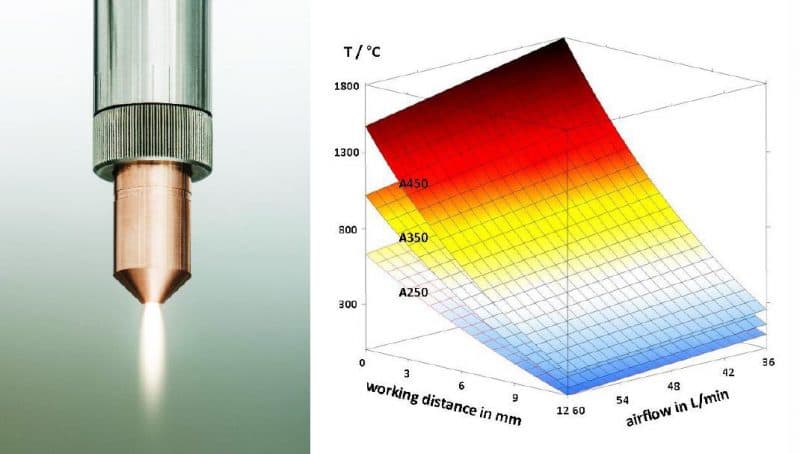

A250 nozzle and static temperature of the nozzle types A250, A350 and A450 used with Plasmabrush® PB3.

When users ask the initially quoted question “How hot is plasma?“, often what they mean is less the temperature of the plasma itself but rather the thermal events occurring on the surface of the substrate treated. In order to specify these temperatures precisely, extensive warmth and infrared measurements are necessary. Based on many years of monitoring applications, Relyon Plasma GmbH has developed a software which makes it possible to simulate the heat transfer of atmospheric or non-equilibrium plasma on a substrate for research purposes. The calculations made differentiate between the type and geometry of substrate surface as well as the settings chosen for the plasma’s electric input power.

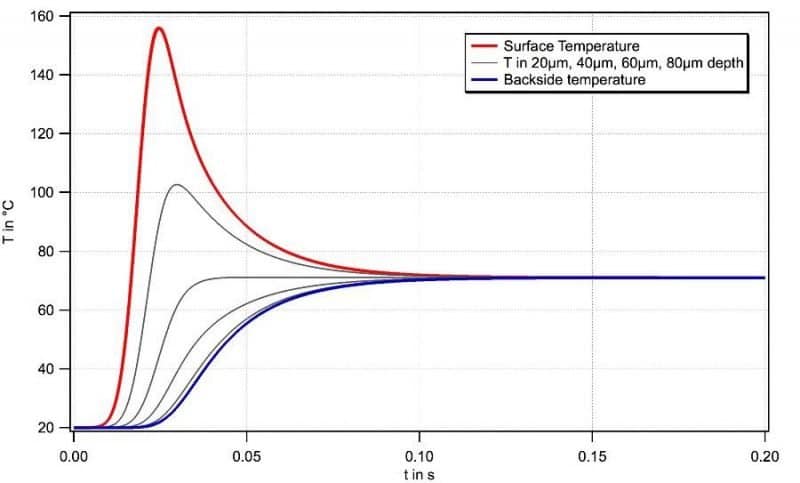

Development of heat during intensive plasma treatment, simulated with Relyon Plasma Software.

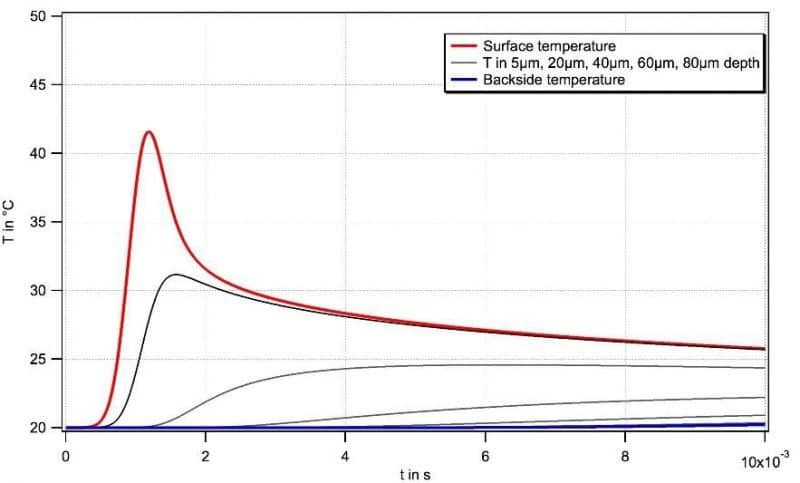

As the results of extensive measurements corroborate, the energy inserted into the surface affects mostly the first layers of a substrate. This makes atmospheric plasma treatment a true surface treatment, as the cleaning and wetting effects are caused by the interaction of the plasma particles with the top atomar layer of the material, without the deeper layers of the material being affected in any way whatsoever. The temperatures effective on the surface do not only rely on the plasma’s electric input power but are also significantly influenced by the type of plasma gas used as well as controlled by the user via the process parameters, with two parameters typically being most important: operation speed and distance between device and substrate. This simple parameterization is absolutely sufficient for most plasma applications.

Development of temperature during gentle plasma treatment, simulated with Relyon Plasma Software.

With some processes such as hot melt or coating it is an advantage to work with a more complex matrix. For this purpose, in addition to the two parameters already mentioned, the device itself offers three more parameter settings (gas flow, frequency and electric input power). In the following, three temperature-critical applications are discussed which require precise process control. The possibilities of the Plas-mabrush® procedure are exemplified by cell culture chips, thin films (here: aluminum foil) and LDPE thin film deposition.

Cell culture chip

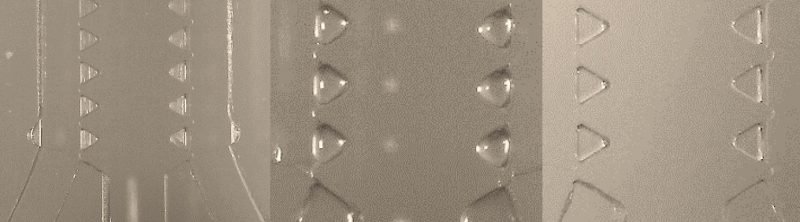

Original chip (left) and details of a damaged (middle) and an undamaged chip (right).

In this project, the microstructured surface of a 3D cell culture chip was supposed to be activated without thermal damage to the cell’s microstructures. The success of the procedure was to be judged by the contact angle of distilled water.

A slight overactivation (excessive energy input into the surface) changes the form of the triangular parts of the chip, as the picture in the middle shows in detail. Only precise optimization of the process parameters makes it possible to treat the sample without thermal effects. Due to the gentler treatment, the surface energy will remain below maximum activation capacity, the angle of contact however is reduced from 92° to 43°. Using the Plasmabrush® PB3 and the A250 nozzle, the process parameters were set at 250 mm/s and a working distance of 40 mm with nitrogen as a feedgas.

Thin film application: aluminum foil

Treatment of aluminum foil in a roll to roll procedure

Due to their minimal thickness, thin films are especially critical in plasma applications. Although there are usually no problems with metals and temperature because of their high conductivity, films have to be handled with great care as they have no layers for heat transfer. Metals of a certain mass can be treated as slowly as 30 mm/s, whereas foils have to be processed at speeds of 500 mm/s and higher.

Roll to roll is an example of such a procedure where each film has to be treated at very high speed, leaving only split seconds for the plasma particles to interact with the surface. Achieving high-quality activation under these conditions is a real challenge; however, a suitable plant layout still allows for successful implementation. As can be seen in the picture above right, in one instance three plasma generators were set up in series at a speed of 12m/s in order to cover the entire width of the foil’s adhesive surface.

LDPE Hot Melt deposition on aluminum

Plasma induced coating is a significantly more complex process as it involves added components for powder transport, which enhances the parameter matrix. In this project, LDPE was supposed to be ap-plied to an aluminum substrate. Hot melt coating achieves the low viscosity necessary for uniformly even layers while the process is much faster than conventional methods as there are no solvents to be removed.

An external system transports the powder to the nozzle exit so that it melts directly on the surface and then cools down there. The system can transport powder rates of up to 7.19g/m. The plasma has two functions: first, the chemical cross-linking of the surface is improved by the particles introduced into the surface, and second, the hot melt spreads better due to enhanced wettability.

The key parameter in this process is speed. It should be set low enough for a uniform coat to form but at the same time high enough to avoid excessive energy input into the surface and the layers that have only just formed. Accordingly, in this application the speed was set to 210 mm/s and the working dis-tance to 14 mm. The component meanwhile was rotating at 14.5 rpm. The entire coating process took six minutes to complete.

Completed hot melt coating (left) and Plasmabrush® with external injection (right).

Conclusion

Even if non-thermal plasmas at high temperatures are used in industrial applications, it is very well possible to treat highly sensitive materials by setting the process parameters accordingly, especially working speed and distance to the substrate. Moreover, this treatment merely modifies the surface of a substrate while deeper layers remain untouched. This makes plasma applications an efficient and at the same time gentle method of treating even those materials which are thermally extremely sensitive for activation and fine cleaning purposes as well as improved wettability.

Bibliography

[1] K. Küpfmuller, W. Fathis und A. Reibiger, Theoretische Elektrotechnik: Eine Einführung, Springer, 2013.[2] H. Zohm, „Plasmaphysik,“ LMU München, München, 2012/2013.

[3] R. A.Wolf, Atmospheric Pressure Plasma for Surface Modification, Hoboken and Salem, USA: Wiley & Sons and Scrivener Publishing, 2013.