Hybrid Dielectric Barrier Discharge Reactor: Characterization for Ozone Production

Authors: Dariusz Korzec, Florian Freund, Christian Bäuml, Patrik Penzkofer and Stefan Nettesheim

Date: 27.07.2024

First published on: https://www.mdpi.com/2571-6182/7/3/31

Abstract

The study investigates the generation of ozone using a plasma reactor based on a novel hybrid dielectric barrier discharge (HDBD). Ozone generation was investigated for a variety of parameters. The classic application of ozone is the treatment of water and wastewater. More recently, the bioactive properties of ozone have been used in numerous applications, e.g. to improve the safety and maintain the quality of food, in healthcare, for therapeutic ozone-induced cell death, for bactericidal disinfection, in the elimination of odors, or in the context of disinfection and sterilization.

Recently, a need for compact, effective and economical generators of ozone and reactive oxygen-nitrogen species (RONS) for medical, biological and agricultural applications has been identified. In this study, a novel hybrid DBD reactor is presented that fulfills these requirements. Its structured high-voltage electrode enables the ignition of both surface and volume microdischarges that contribute to plasma generation.

How the HDBD reactor works

The preferred method for generating ozone-containing gas is dielectric barrier discharge (DBD) in both oxygen and air. Two main types of DBD are widely used: volume DBD (VDBD) and surface DBD (SDBD). The main difference between them is the way in which the microdischarges develop. In this work, an HDBD reactor is presented that combines the advantages of both discharge geometries.

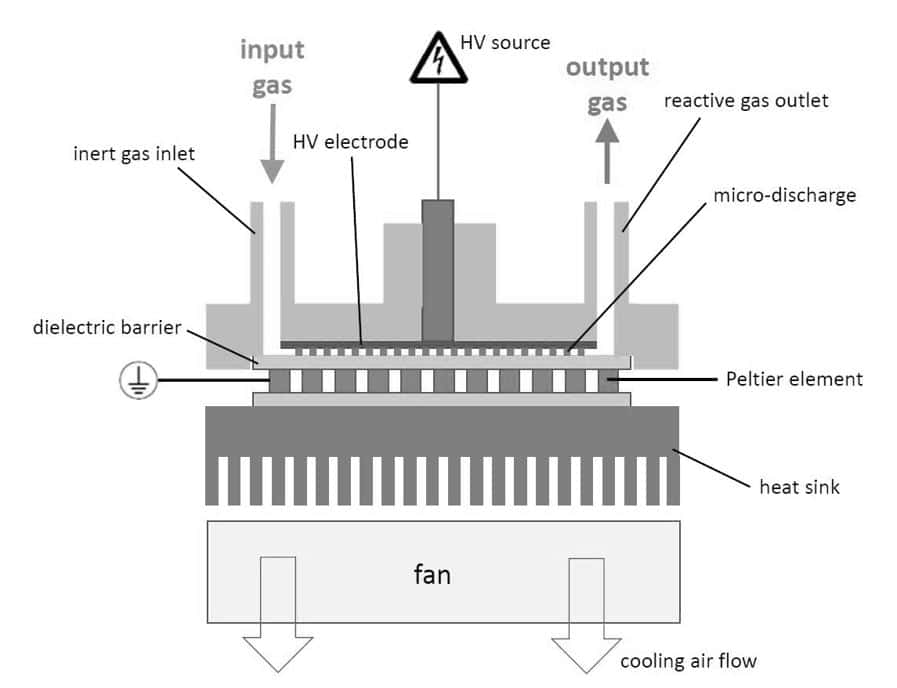

The HDBD reactor used in this work is based on a modified rectangular parallel plate architecture with a dielectric barrier and is shown schematically in cross-section in Figure 1. It is supplied with high voltage from the associated, also newly developed high voltage generator.

What is new about this reactor is its structured high-voltage electrode (HV) made of stainless steel, which enables HDBD, and the built-in Peltier element. Among other things, this acts as a dielectric barrier. The use of Peltier cooling instead of pure air or water cooling enables better controllability of the heat dissipation from the discharge zone. The reactor operates with an electrical power consumption of less than 30 W and a high-voltage frequency of several 10 kHz.

The micro-discharges are ignited between the HV electrode and the aluminum oxide plate of the Peltier element. The p-n junctions in the Peltier element serve as an earthed electrode.

Experimental Setup

The performance of the HDBD reactor for ozone production was investigated for a variety of parameters that influence the specific energy input (SEI): the input voltage of the high-voltage generator, the gas flow, the pulse width modulation (PWM) duty cycle and the current of the Peltier element. Different gases such as oxygen, synthetic air and dry compressed air were tested to determine their efficiency in ozone production. The ozone concentration was measured by UV absorption and higher harmonics of the discharge current were used to monitor the net discharge performance. Overall, the reactor was designed to maximize ozone production through optimized gas flow and temperature control.

The highest ozone concentrations achieved without Peltier cooling are 23,500, 3,500 and 3,200 ppm for pure oxygen, synthetic air and CDA respectively. The maximum production rates for the three gases are 3.2, 0.897 and 0.785 g/h.

Summary

A major advantage of the presented HDBD system is the efficient ozone generation at low temperatures, which can be actively adjusted by temperature control through the integrated Peltier element. The study also emphasizes the importance of humidity control for the efficiency of ozone production.

The results of HDBD operation shown in this paper are only the beginning of research into this novel type of discharge. The simple, compact, efficient and cost-effective design enables many novel applications in various industrial and medical fields.

You can read the whole article here.