implaPrep concept

Plasma activation of implants

The functionalization of medical and dental implants e.g. with the implaPrep concept serves to optimize the wetting behavior. Materials used in medical technology, such as zirconia ceramics or titanium and stainless steel, but also PEEK, Teflon, silicone and highly filled polymers, can be effectively optimized in their wetting behavior by plasma pre-treatment. This property is the basis for biocompatibility and acceptance by the surrounding living tissue. By increasing the surface energy the initial attachment of osteoblasts is improved, which subsequently leads to increased new bone formation after implantation. Thus, surface activation with plasma can improve bone regeneration, leading to increased and accelerated osseointegration. This is particularly important in complex cases, immediate loading, or compromised patients.

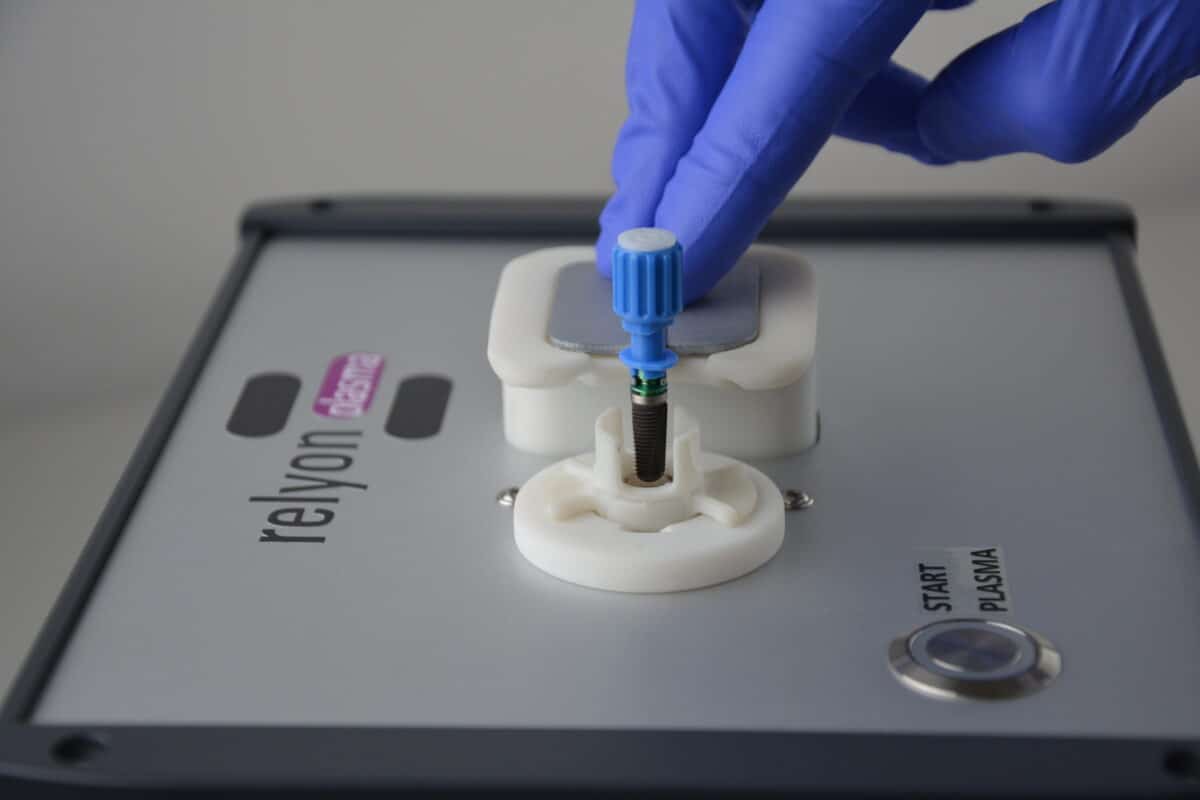

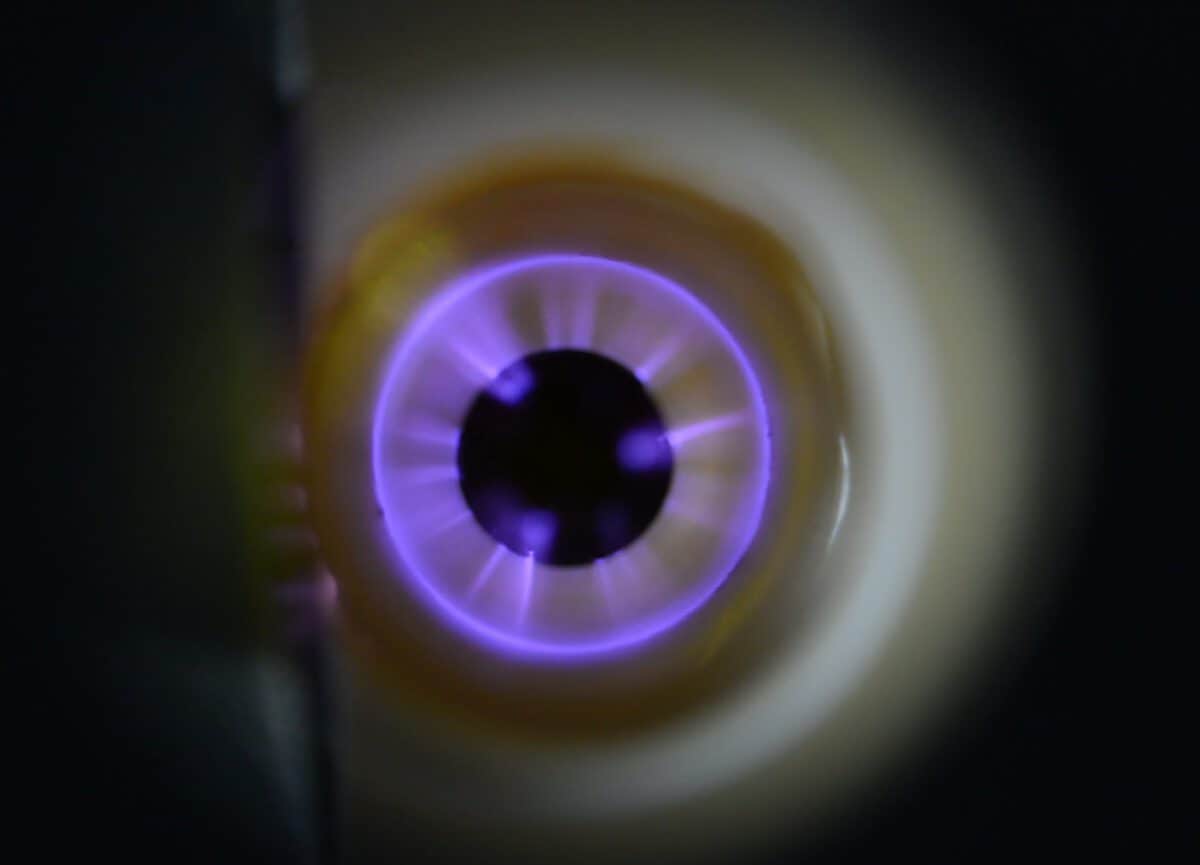

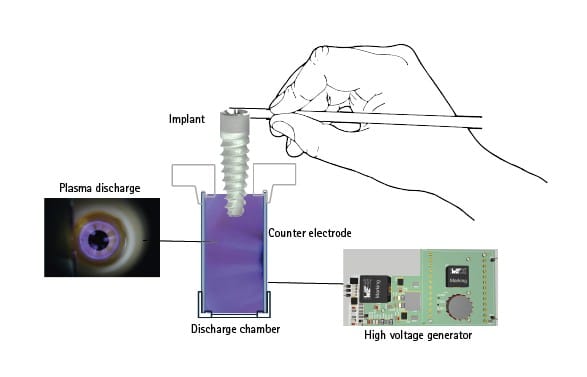

Activation of the implant surfaces with implaPrep is a supportive procedure that is used by an implant dentist, oral surgeon, or oral and maxillofacial surgeon prior to the insertion of the implants into the jawbone. The material and surface structure specified by the manufacturer is not changed by this process. Surface activation is achieved by an atmospheric dielectric barrier discharge on the implant, which removes microscopic carbon-based adsorbates from the surface, increasing surface energy and improving implant wettability. This enhances the interactions of proteins and cells with the implant surface at a molecular level.

Field of application

- Activation and functionalization of implants made of a wide variety of base materials

- Improvement of wettability

Possible use

- Chairside during implantation as a stand-alone device

- Integration in existing devices

Technology

Plasma components

Our plasma components for the activation of implants are developed according to ISO 13485. This enables easy and safe integration into a medical device or a stand-alone chairside device.

Plasma reactor

- DBD (dielectric barrier discharge) plasma generator with implant as counter electrode

- Sterile barrier to the implant

- Effective cooling of the implant during and after activation

- Contamination of the implant in the reactor is impossible

- Safe to use, sterilizable, biocompatible

Plasma driver

- Provides the required high voltage for plasma activation

- Easy control via analog on/off signal or supply voltage

- Plasma monitoring and provision of an analog process signal

- Robust and safe technology

Advantages

The advantages of the implaPrep concept are obvious:

- Small and compact

- Short treatment time approx. 30s

- No overtreatment possible

- Extremely safe and easy handling for the end user

- Very energy efficient and environmentally friendly

- no auxiliary materials such as chemicals or additives required

- Highly efficient and safe excitation of the gas molecules

- Extremely high power density of the compact device

Application examples plasma and implants

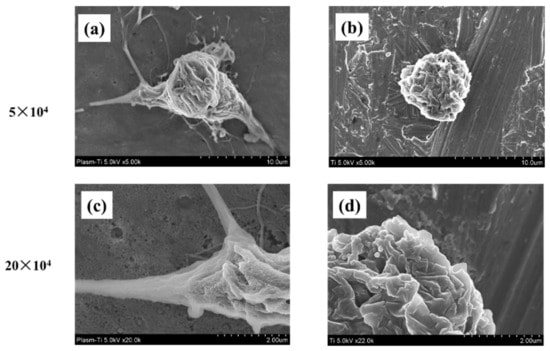

Effects of Plasma Treatment on the Bioactivity of Zirconia Implants

Takao et al. investigate in vivo and in vitro the effects of plasma treatment on the bioactivity of zirconia/alumina nanocomposites (NANOZR) used as implant materials.

Plasma Treatment on Titanium Surfaces for Implants

The work from Tsujita et al. investigates the effect of surface modification of titanium implants on bone formation. Especially cold atmospheric plasma treatment shows promising results.

Surface Energy Analysis of Dental Implants

Surface Energy Analysis of Dental Implants after Plasma Activation with the piezobrush® PZ3 with the DataPhysics Instruments OCA-PDDS

Press release: Plasma in the medical sector

Relyon plasma presents the versatile application possibilities of atmospheric pressure plasma within the webinar series “Plasma in the medical sector”. Starting with the production of medical products, through the dental industry to direct use in medicine and skin treatment.

Technical data implaPrep

- Electrical power: 25 W

- Electrical voltage: 10-30 V, 24V typ.

- Typical process duration (including cooling): 45 s

- Typical final implant temperature: 38°C

- Maximum implant temperature: 60°C

Functionality

An atmospheric dielectric barrier discharge is ignited onto the surface of dental implants made of titanium, for example. This removes carbon adsorbates, increasing the surface energy and improving the wettability of the surface. The plasma-activated surface promotes initial osteoblast attachment, optimizing osseointegration.

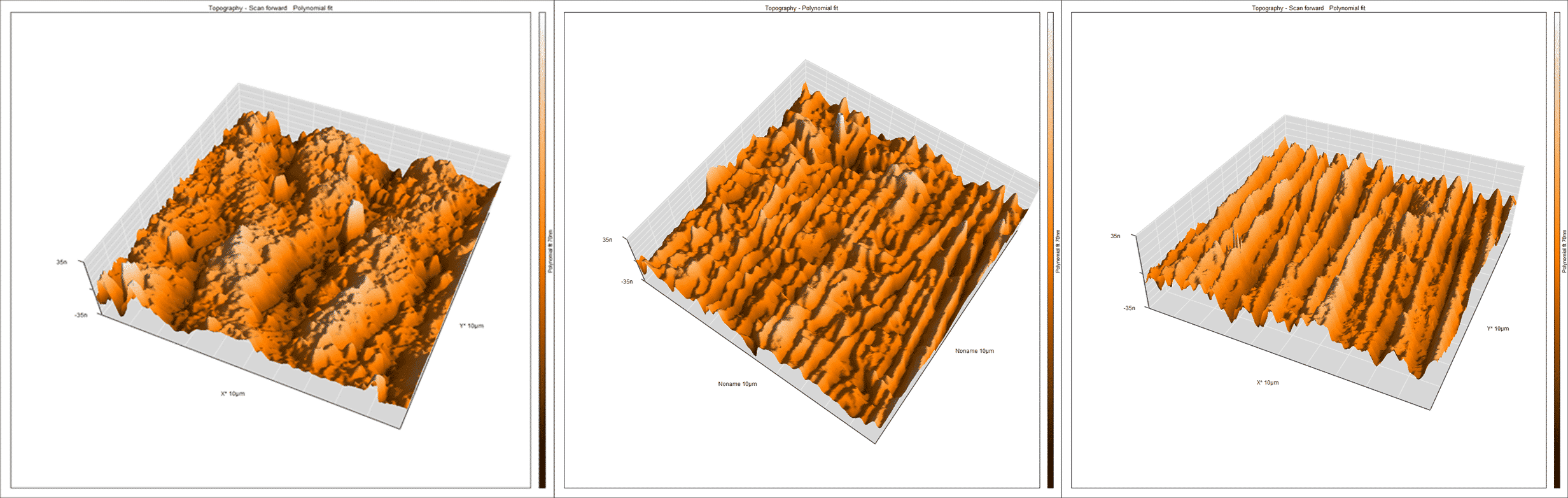

The improved surface property of the implant is achieved without changing the surface roughness (topography) and without changing the material composition (stoichiometry).

The safety of the process is enabled by an electrical contact to the transfer post of the implant, the activation itself takes place via a non-contact discharge in an air gap between the implant and an inert dielectric surface. There is no material exchange with the dielectric counter electrode and the temperature of the implant increases only slightly during the process.

The process time is less than 30s, typically 20s. Even with an over treatment of 2 minutes, it can be determined that the surface topography has not changed. The process is thus stable and reproducible. In addition, the process is very safe, as it is non-invasive and takes place without direct contact with the patient.

Cooperation

What we offer

- Components (Driver & Reactor) developed according to ISO 13485

- Validated activation process

- System and integration know-how

Partners we search for

- System integration

- Device approval (possibly MP Class I)

- Worldwide distribution of the finalized device

Downloads

| Description | Language | Download |

|---|---|---|

| Flyer | DE | Flyer |

| Flyer | EN | Flyer |