Cleaning industrial parts with plasma

A clean affair

Published: June

Magazine: JOT Journal für Oberflächentechnik – SPECIAL Industrielle Teilereinigung

Topic: Cleaning industrial parts with plasma

Author: Corinna Little

On functional and connecting surfaces, cleanliness is key for the quality of subsequent processes such as gluing, coating or printing. Atmospheric pressure plasma is an environmentally friendly cleaning technology suitable for inline application.

Contaminants on components can lead to considerable difficulties during further processing. Especially on functional and connecting surfaces, cleanliness is decisive for the quality of subsequent processes, such as gluing, painting, coating or printing. Wet chemical cleaning processes play a major role for historical reasons, but are now competing against more environmentally friendly and inline-capable alternative technologies, such as cleaning with atmospheric pressure plasma. The possibilities of this technology range from fully automated cleaning solutions with high processing speeds to flexible use at manual workstations.

Plasma, the so-called fourth state of matter, is created by the energetic excitation of a gas. Under atmospheric conditions, process gas can be transferred into the plasma state by an electric arc. [1] One example is the Pulsed Atmospheric Arc Technology (PAA Technology®), in which the arc between two electrodes is stabilized by the vortex flow of the process gas.

Tuning process gas according to the type of contamination

Knowing the type of contaminants to be removed is crucial for the choice of process gas. In the case of organic films, which typically occur on components as a result of previous processing steps, the active oxygen species in an atmospheric compressed air plasma cause the organic to oxidize. At the same time, the temperature of the plasma causes sublimation or evaporation of residues on the surface. The process temperature in the plasma flame can be set over a wide range from a few 100°C to over 1000°C by carefully selecting the process parameters.

Even thicker layers can be removed

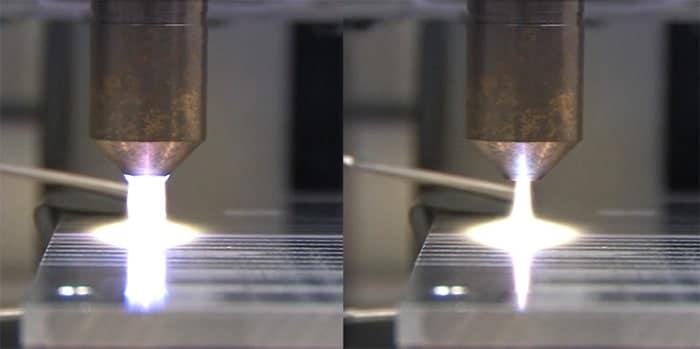

The temperature of the arc itself is several 1000°C, which can be used in the operating mode of the so-called transferred arc: With conductive, grounded substrates, the arc can be transferred directly onto the surface (see Fig. 1). Due to the high power densities in this operating mode, even thicker layers can be removed from the surface or metal surfaces can be effectively cleaned and slightly roughened at higher speeds. This operation of a so-called cathodic cleaning is possible by the generation of the arc by unipolar pulses. These can be set in a range between 40 and 64 kHz, which further improves the capacitive coupling into the layer to be removed.

Effective removal of numerous contaminations

But even in standard mode, in which the arc burns stabilized by the gas flow on the grounded nozzle, surfaces can be effectively cleaned of a variety of contaminants. A good example for this is the cleaning of metals before roll cladding, as it is used, for instance, in the production of bimetallic strips. The two metallic bonding partners not only have to be free of oil or lubricating films, but also of oxide layers. The plasmabrush PB3 system can be operated with different process gases due to the gas supply at the generator.

Thus a compressed air plasma can first remove organic impurities and in the next step a reduction of oxides on the surface can be achieved with the same system by changing to a hydrogen-containing process gas, typically forming gas 95/5.

Cleaning different materials

The fields of application of atmospheric pressure plasma range from the cleaning of metallic substrates, glass and ceramics to natural materials. With most polymers, plasma treatment also leads to so-called “activation” of the surfaces, in which the molecular end groups are modified so that wetting can be improved and subsequent processes are optimized.

The generation of an arc using PAA Technology® requires an input power of almost 1 kW. But even in the lower power range from 10 to 30 W, an effective plasma can be generated by direct electrical discharge at an open piezoelectric transformer (Piezoelectric Direct Discharge Technology – PDD Technology®). The temperature of the plasma does not exceed 50°C, making it an ideal alternative for temperature-sensitive materials and manual fine cleaning processes.

While the disposal of the partly health-endangering substances often poses a problem for wet chemical cleaning processes, the “waste products” of the atmospheric pressure plasma are gaseous or volatile and can easily be extracted by appropriate plant technology or neutralized by means of activated carbon filters.

If you have further questions about industrial parts cleaning with plasma, please contact us.

[1] Wolf, Rory A., Atmospheric Pressure Plasma for Surface Modification, Wiley, 2012

You can find the original article here.