Influence of the β– Radiation/ Cold Atmospheric Pressure Plasma

Surface Modification on the Adhesive Bonding of Polyolefins

Published January 2021

Bednarik, M.; Mizera, A.; Manas, M.; Navratil, M.; Huba, J.; Achbergerova, E., Stoklasek, P.;

Materials,(2021) 14. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7795023/

Executive summary

One of the most common applications of cold atmospheric pressure plasma is the activation of polyolefines, such as polypropylene (PP) prior to an adhesive process. Bednarik et al. performed a comparative study on the influence and effectiveness of cold atmospheric pressure plasma and β– -radiation on the wetting contact angle, free surface energy, its polar component and the adhesive properties.

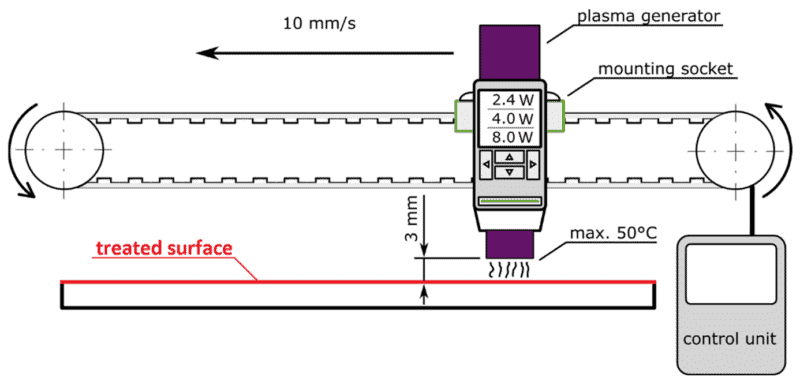

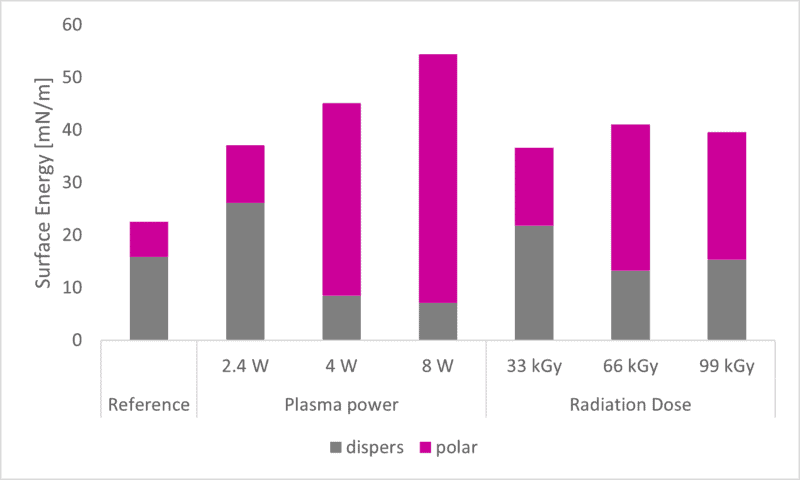

For the investigation, two systems were applied to activate the PP surface, for the cold plasma activation the piezobrush® PZ3 (relyon plasma, Germany) and for the β– -radiation (accelerated electrons) a Rhodotron high-voltage accelerator (Tongeren, Belgium), which presented the maximum energy of 10 MeV was applied. Different power settings respectively dose settings were applied. The surface energy could be increased for all dose/power settings compared to the reference, with the highest values of the surface energy of 54.4 mN/m achieved with the plasma treatment. Especially the polar fraction could be increased with both pre-treatments.

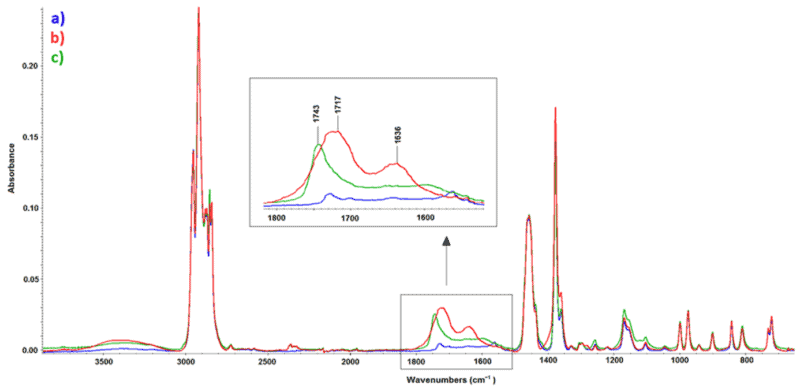

The origin of this polar component was determined with FTIR-measurements, where a great difference between the spectra could be determined in the region of 1850 – 1600 cm-1, which confirms the formation of carbonyl functional groups in the PP polymer chain. Additionally, in the signal in the spectral range of 3600 – 3100 cm-1 was enhanced via the treatments, indicating the formation of hydroxyl functional groups.

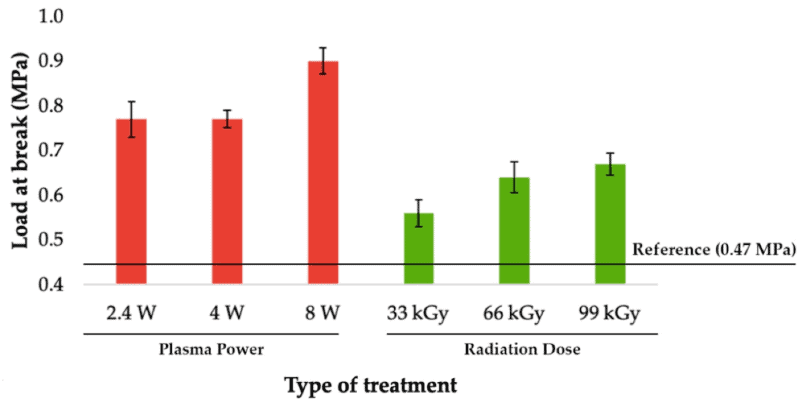

Load bearing capacity of bonded joints

For most applications the most important value of adhesive bonding, is the load bearing capacity of bonded joints. This parameter was determined by measuring the shear strength of the bond with tensile test. The surface treated by both aforementioned methods, i.e., cold plasma and β- radiation, displayed a significant increase of the bond’s strength for every type of tested adhesive, i.e., cyanoacrylate-, acrylate-, and epoxide-based. The strength of the adhesive bond connecting the virgin materials was taken as a reference point.

Summary

In this work the effects of β–radiation and cold plasma on PP were investigated. Both methods had a positive effect on both the wetting and the surface energy of the tested material. The adhesive properties of the polymer specimens were significantly improved by both β− radiation and cold plasma treatment. The results proved, that β− radiation is on the similar level of effectiveness as plasma treatment, as far as improvements of adhesive bond’s strength and adhesiveness of PP are concerned. This is especially astonishing, taking into account the different sizes of the devices: The piezobrush PZ3 is a handheld device, while the β− radiation system is an almost room filling highly specialized device.

More about the piezobrush® PZ3 >>