Inorganic materials

Inorganic materials like:

- Glass

- Ceramics

- Stone

The surfaces can be finely cleaned on the one hand, and the surface energies can be increased on the other.

Glass

Plasma treatment of glass surfaces has been established in practice for many years. Without pre-treatment, glass has a surface energy of 47mN/m. After plasma treatment, the surface energy increases significantly. When treated with the plasmabrush® PB3 high-conductivity plasma system, a surface energy of >72mN/m is achieved, and with the piezobrush® PZ3 handheld plasma device, a surface energy of >67mN/n is achieved. Test inks according to DIN ISO 8296 were used for the verification.

Plasma treatment of glass is used, for example, to improve adhesion between glass and PDMS or to prepare glass for digital printing. This is particularly important because glass is very difficult to print without pre-treatment and the print result often leaves much to be desired.

Application example bonding of glass

A typical application example is the bonding of glass. The following table shows an overview of the increase in average bond strength after surface treatment compared to untreated glass substrates.

| Substrate | Glue | Treatment | Medium Adhesive strength | STABWA | Increase |

| Glass | Epoxy resin | none | 1,46 N/mm² | 0,43 | |

| Glass | Epoxy resin | piezobrush | 5,43 N/mm² | 0,37 | > 3,7-fach |

| Glass | Power Adhesive | none | 2,80 N/mm² | 0,62 | |

| Glass | Power Adhesive | piezobrush | 3,85 N/mm² | 0,49 | > 1,3 fach |

| Glass | Windshield adhesive | none | 0,23 N/mm² | 0,02 | |

| Glass | Windshield adhesive | piezobrush | 0,85 N/mm² | 0,04 | >3,5 fach |

Application examples

Plasma activation of CFRP and glass

The Max Planck Institute for Astronomy uses the piezobrush PZ2 for plasma activation of CFRP and glass/glass ceramic adhesive surfaces.

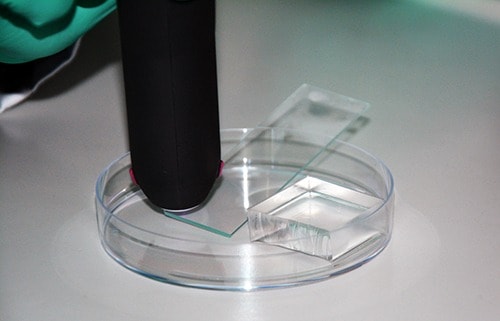

Sabine Schmidt from ISAT at Coburg University reports on the use of plasma in microfluidics to achieve a connection between PDMS and glass substrate.

Adhesion improvement glass and PDMS

During a visit to the laboratory of biofluid mechanics at OTH Regensburg, experiments to improve the adhesion of glass and PDMS with plasma took place.

Pre-treatment for glas printing

How can you prepare glass for digital printing to create a durable product? We provide a brief overview of pre-treatment for glas printing.