More than air

Structural Gluing of Semi-Crystalline Polymers through Atmospheric Plasma Treatment

Many thermoplastic materials are very difficult for structural gluing. Activation with atmospheric plasma significantly increases the adhesive force of the joint in just one process step. The search for the cause harbors some surprises.

The effect of plasma treatment on a surface is of a thermal, chemical, and electrical micromechanical nature, and depends on the chosen process parameters. Factors that play an important role include the working distance, type of process gas, excitation power level, and processing speed, but also the properties of the substrate. Semi-crystalline polymers have some characteristics that make them especially well suited for plasma pre-treatment so that the adhesive force of a bonded joint can be significantly increased. Interesting effects are revealed when the reasons are investigated in greater detail.

Model System and Tests

A polyoxymethylene homopolymer (POM-H) was chosen as the model system for testing. With a degree of crystallization up to 90%, it is opaque white in color due to its high crystallinity and remains unchanged up to the melting temperature of approximately 175–178°C. POM starts to thermally decompose at around 220°C and releases formaldehyde.

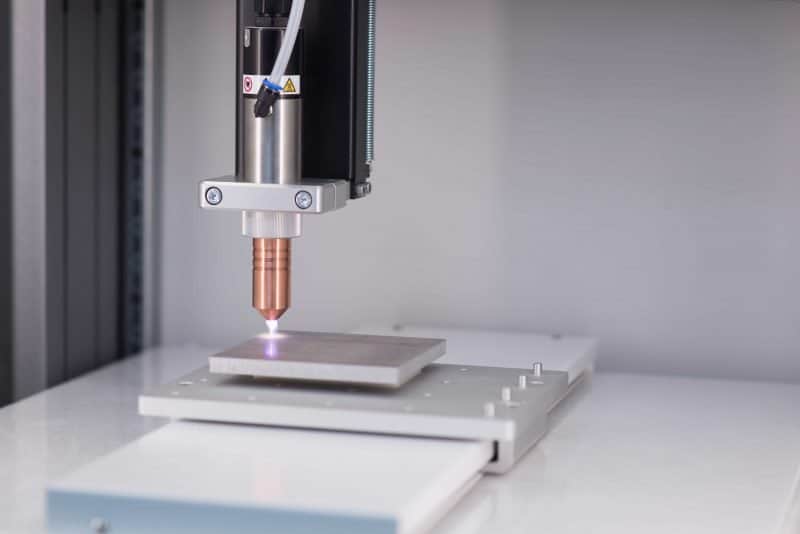

A typical two-component epoxy resin adhesive system was used for the structural gluing tests (ESK-50 fast-acting epoxy resin adhesive from Würth, Künzelsau). All tests were conducted with an integrated atmospheric plasma system (type: Plasmacell 300, manufacturer: Relyon Plasma GmbH, Regensburg).

Tensile/shear tests confirmed a significant difference with the adhesive force being several times greater. Two main reasons are usually given for this improvement in the quality of bonded joints after plasma activation: Better wettability of the surface and the removal of residual contaminants (changed chemical composition of the surface). This makes it all the more astounding that a third aspect appears to play the most important role for thermoplastic polymers: The temperature increase during treatment.

Wettability of the Surface Is Increased

The wettability of the surface gives an initial indication of the surface treatment effect. It can be easily made visible by applying a liquid test ink. One can clearly see the increased wettability of the line swept by the plasma flame with a certain width. Here a striking aspect is that, starting from the untreated surface energy (area A) of approximately 40 mN/m, the highest surface energy is found directly at the edge of the visible trail (area B). A more detailed analysis by means of contact angle measurements shows that the maximum surface energy with atmospheric plasma treatment at approximately 58 mN/m is reached prior to visible clouding of the surface. However, the maximum adhesive force with the two-component adhesive being used is not reached in this state of maximum surface energy, but at a processing intensity where the surface has already changed visibly and the surface energy has decreased again to approximately 52 mN/m (area C). Thus, simply examining the surface energy is not sufficient for specific optimization of the bonded joint.

Contamination is Reduced

Even small traces of contaminants can significantly decrease the joining quality in the structural gluing process. Time-of-flight secondary ion mass spectrometry (TOF-SIMS) with secondary ions released from the surface was used for a chemical analysis of the surface with high sensitivity and spatial resolution.

In addition to the mass signals characteristic for POM (for instance m = 31, 61, 98), some contaminants such as sodium (m=23), silicon (m=28) and traces of a silicon material (PDMS; m = 147, 221 and 281) are found on the untreated specimen. The intensity of the mass signals characteristic for POM increases after plasma treatment and the signals interpreted as contaminants decrease. This effect is shown in Figure 2 using mass 61 as an example; presenting the complete mass spectra is omitted. One thing is for certain: Plasma treatment has effectively cleaned the surface. However, specimens carefully cleaned with solvents did not do better in tensile/shear tests than the untreated surfaces in this case. It therefore seems likely that removing residual contaminants alone cannot be the central factor explaining the improved adhesive force after plasma treatment.

A look at the literature shows that the contribution of functional chemical surface groups for the joining of various polymer materials in principle is well known [2]. It is often assumed that the functional groups on the surface make the greatest contribution to the adhesive force between the substrate and adhesive. That these functional groups can be specifically integrated on the surface through atmospheric plasma treatment [3] and thus among other things change the surface energy is known. The quantitative contribution to the technically relevant quality of the joint is certainly often debatable and difficult to quantify.

However, we observe very little difference in the practical effect on the quality of the bonded joint when the plasma process is converted from air (containing 21% oxygen) to nitrogen (see Fig. 1). Changing the adhesive to a modified methyl methacrylate adhesive also changes little. It is therefore questionable whether the quality of the bonded joint is dominated by chemical surface groups in this case.

Optimized Cross-Linking of Polymer Chains

Examining the temperature development during application is particularly revealing for answering the question of where the improved adhesive force for bonded joints of crystalline thermoplastic materials after plasma treatment comes from (Fig. 3). Given the typical power densities and travel speeds of atmospheric plasma treatment, the temperature of the substrate surface and layers close to the surface is briefly increased [4]. Here the great dynamics of heating the surface followed by very rapid cooling are especially interesting. The heating/cooling rates can exceed 5000 K/s at travel speeds of 100 mm/s.

Beyond a certain threshold, the phase change temperature of the polymer is exceeded in this layer. However, both the heating and the cooling phases are limited to this thin layer and to a short time. Therefore this dynamic temperature effect determines the melting and crystallization behavior of the polymer material in this layer. In contrast to a thermoplastic polymer that solidified after bulk melting, new phase mixtures are now created on the surface and down to a depth of a few µm.

Starting at a certain thermal surface load, visible clouding of the POM specimen can be seen even with the naked eye (see Fig. 2). However, this is not due to roughening of the surface as one might assume. In fact, small irregularities such as scratches or point defects tend to be smoothed out by plasma treatment. The fine granular structures indicate a mixed phase of amorphous and crystalline zones that have frozen due to rapid cooling and therefore coexist in a thin layer [5, 6]. A change in the refraction of light and the resulting diffuse scattering accounts for the matte visual appearance. A structural change is clearly discernible in the AFM images (Fig. 2). However, the images confirm that the filament structures occurring after the intensive plasma treatment correspond to only negligible roughening of less than 0.2 µm. The granular structure is indicative of spherulites close to the surface that typically develop during melting and incomplete crystallization processes [6].

It is known from the literature that the diffusion of components with a low molecular weight is much higher in the amorphous phase than in the crystalline phase [7, 8]. When an adhesive that hardens through polyaddition is now applied to an amorphous polymer structure, the monomers can diffuse very well into the open structures of the amorphous polymer prior to complete hardening. The better adhesion achieved with reactive adhesives is therefore based on optimized cross-linking of the adhesive’s polymer chains with the polymer chains of the substrate (Fig. 4).

Summary

Through a combination of various methods, it was possible to show that a thermally induced phase change from crystalline to amorphous can be observed for surface treatment with an atmospheric plasma burner using the thermoplastic polymer POM as an example. This plays a crucial role in improving the joining properties with reactive two-component adhesive systems.