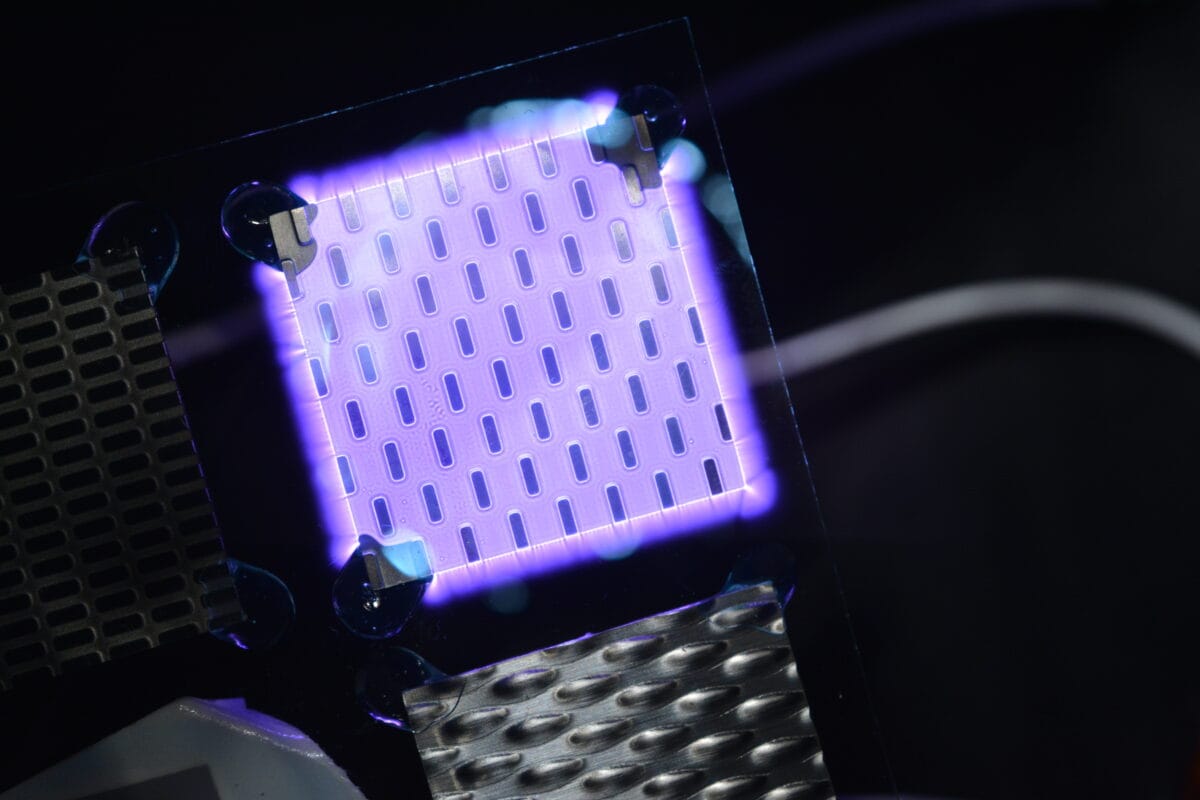

MediPlas Output

MediPlas™: more than a simple ozone generator

Medical | Dental | Pharma | Packaging | Food

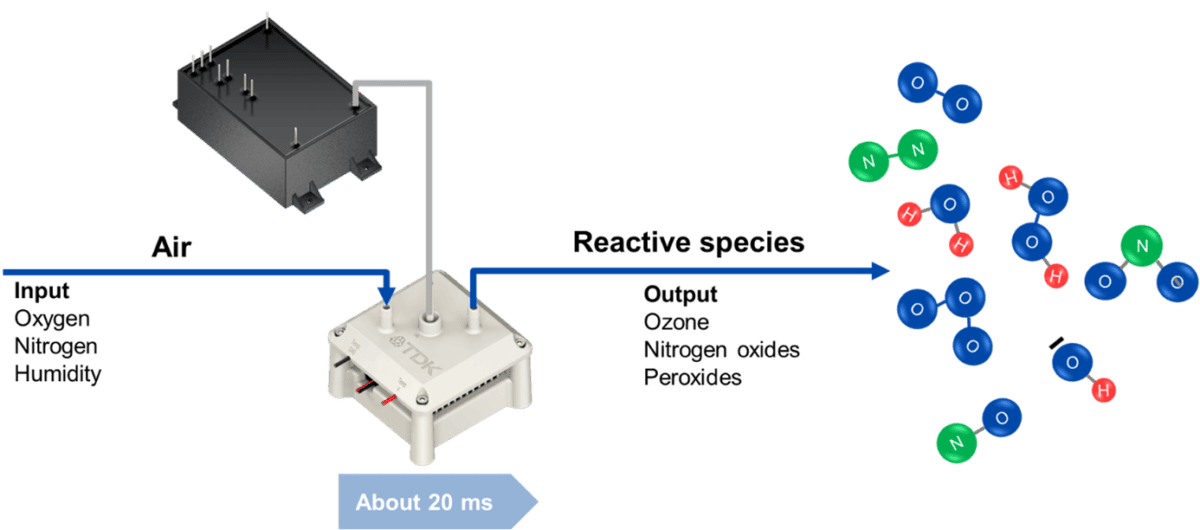

In essence, the chemistry of the plasma discharge is influenced by numerous parameters, of which only a subset can be adjusted independently. Extensive data has been gathered on this matter, though it won’t be expounded upon in this discussion. Nevertheless, for the prevalent practical scenario involving the utilization of air as the working gas, it is possible to streamline the most critical operational modes.

Typically, we can categorize the various modes of operation as follows:

High Ozone Output:

Achieved when utilizing pure (dry) oxygen, obtained, for example, through pressure swing adsorption (PSA). Maximum concentration is reached by maintaining a cold reactor using the integrated Peltier cooler and keeping power density at a moderate level.

When compressed dry air is employed, the best ozone concentration is achieved at relatively low power density and optimal cooling. (For more detailed information, please refer to the comprehensive application note and consult the datasheets.)

High NOx Output:

This mode is activated when compressed dry air (CDA) is passed through the reactor while increasing the temperature and power density. In this case, ozone levels will start to decrease in favor of a rising concentration of various nitrous oxides with different oxidation states (NO2, N2O4, N2O5).

Peroxide Formation

Peroxides are generated in the presence of humidified input (water). These peroxides are highly reactive towards ozone and nitroxides, acting as precursors to higher oxidation states of nitrous oxides and acid formation.

Acid Formation:

Acidic species such as nitrous acid (HNO2) and nitric acid (HNO3) are formed in the presence of water and nitrous oxides.

To the MediPlas Reactor product page >>