Optimised adhesive bonding with plasma

Relyon plasma GmbH, a subsidiary of TDK Electronics AG, based in Regensburg, Germany, will be presenting various atmospheric pressure plasma systems for the preparation of surfaces prior to bonding or encapsulation at Bondexpo in Stuttgart.

Regensburg/Stuttgart. From the 7th to the 10th of October 2019 Bondexpo, the international trade fair for bonding

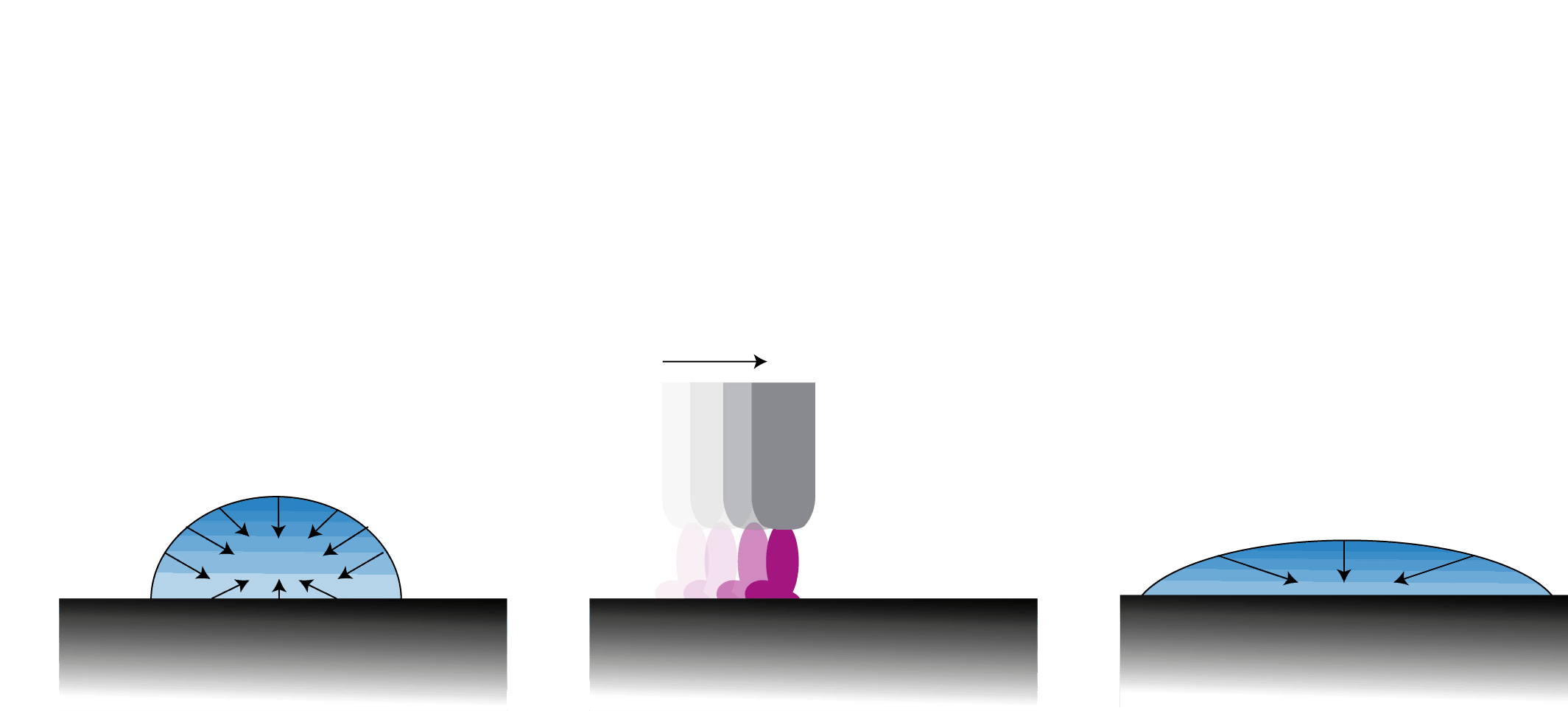

Mechanisms of plasma for bonding

If a surface is functionalized with plasma before bonding, the resulting joints show a significant improvement in adhesion. Animal Care Technologies GmbH describes its experience as follows: “Only with the

Plasma can be used on a variety of materials: Metal, glass, ceramics and even natural materials such as wood and textiles react very well to plasma functionalization. In addition, many polymers with poorly wettable surfaces can be successfully bonded after plasma treatment. Metals, on the other hand, can be cleaned of both organic films and hard oxides, restoring the pure metal surface. This significantly improves many subsequent joining processes such as gluing, coating, soldering, etc.

The perfect plasma system for every application

The atmospheric pressure plasma systems are available in various designs, so that they are optimised for the respective application. The high-performance plasmabrush® PB3 system was specially developed for very high process speeds and integration into industrial production lines. As a counterpart it is also available as plasmatool, a high-performance hand tool for workpieces which cannot be machined due to their size or mobility. In addition, this system is also available as plasmacell, an independent and compact all-in-one system.

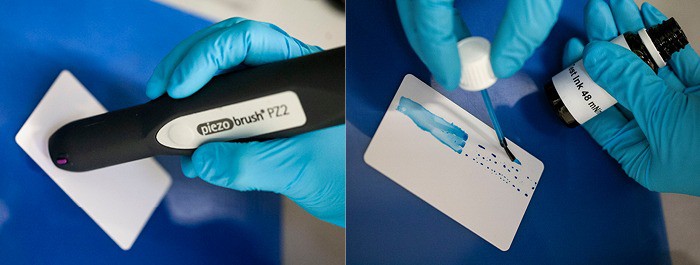

Since these plasma systems are often too large and too costly to purchase for small companies and start-ups, the plasma handheld device piezobrush PZ2 is available for processes from prototyping up to serial manufacturing. “For a start-up company such as ours, the use of a conventional industrial plasma system is hardly conceivable, but thanks to the innovative piezo technology from relyon plasma, professional adhesive bonding is also possible without large investments.” summarizes Doris Hoffmann from Animal Care Technologies.

Advantages in comparison to conventional processes

The relyon plasma atmospheric pressure plasma systems typically work with ambient or compressed air, in special cases also with industrial gases such as nitrogen or forming gas. Compared to the use of primers, atmospheric pressure plasma offers an enormous improvement in terms of economy, process reliability and environmental compatibility. Moreover, this type of plasma does not require expensive vacuum technology. Due to the extremely fast processing speed, atmospheric pressure systems are suitable for a variety of industrial applications.

At the booths of relyon plasma or John P. Kummer, the various plasma systems will be presented and demonstrated directly at the exhibition and can also be tested on-site.

Here you can download the complete press release “Optimised adhesive bonding with plasma”.