Plasma cleaning – paint stripping and cleaning with plasma

Until now, atmospheric plasma treatment has been regarded more as a fine cleaning technique – i.e. plasma cleaning – that only acts on the immediate surface. A clean removal of large contaminations or thick layers was not possible until now. Read all about the topic in the following article: Plasma cleaning – paint stripping and cleaning with plasma.

Typically, thick layers (>1/100 mm) were always first removed mechanically, for example by grinding, sandblasting or brushing, and then post-cleaned. This creates large amounts of dust and can damage the product surface. Another well-established process is burning off with flame or hot air. Although this does not produce dust, it does produce a high emission of hazardous combustion gases, depending on the composition of the layer.

Wet-chemical processes with aggressive stains are also not harmless when used. Residues of the pickling can later lead to component corrosion and must therefore be completely removed after the process. Modern processes, such as laser cleaning or dry ice blasting, are not applicable in all cases and may be very cost-intensive. Dry ice blasting requires a continuous supply of CO2 abrasive. For the application of a cleaning process with atmospheric plasma, only a mains connection and

compressed air are required.

Basic principle of plasma treatment

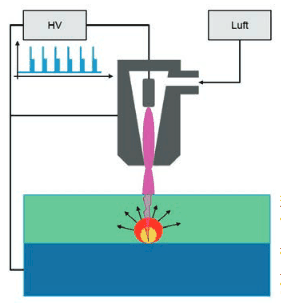

In order to effectively remove a layer from a surface, the best point of attack is in principle the interface between the two materials. If it is possible to focus the power of the removal mechanism precisely on this inner surface, the efficiency of the process is highest. In this case, it is not necessary to remove the entire layer thickness step by step, but the interface is stressed so much that the layer detaches. An atmospheric pressure plasma torch, whose voltage source generates a high voltage swing, can now be operated in such a way that an electrical breakdown occurs in an insulating or poorly conducting layer on a conductive material and a high energy is released in pulses at the transition from the insulating layer to the conductive substrate. With short pulses, a thermomechanical pressure wave is released at the interface and the layer is blasted free at a defined point. If the plasma flame is operated at a high pulse frequency and scanned over a surface, contiguous areas can be easily exposed.

Practical investigation and application

With this innovative process, it has been possible to effectively remove layers of paint more than one millimeter thick with a plasma jet. Only a very small amount of burn-off occurs and the product surface is hardly subjected to thermal stress or mechanically damaged. The result is a clean surface with a fine roughening that is ideally prepared for further processing steps. Bonding, contacting or coating are possible options here.

For the tests, the plasma system plasmabrush® PB3 was integrated into an XYZ axis unit (plasmacell 300) and operated in “ablation mode”. In this system, raster speeds of up to 800 mm/s are possible. The plasma ablation process can be automated or manual. This means that even difficult and angled areas can be easily reached. All conductive substrates are suitable, for example sheet metal, aluminum, steel, copper or conductive carbon fiber structures. The paint layer does not have to be conductive.

Plasma blasting offers great application flexibility and can be used for the following coating systems, among others: Release agents, sizing, product residues, adhesive and glue deposits, polish residues, bitumen, waxes, paint layers, flux deposits. The areas of application are in production, maintenance and service in almost all industrial sectors.