MediPlas components

The MediPlas components of the MediPlas system consist of a high-performance RONS generator and the appropriate driver, which can be used in a wide range of applications as well as for disinfection.

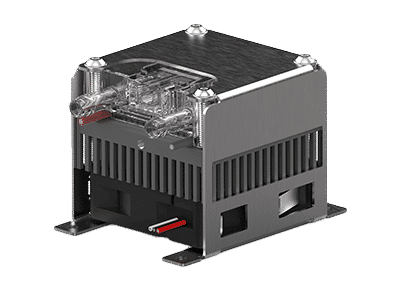

MediPlas Reactor

The MediPlas Reactor is our high-performance RONS generator. It can be used as a component for desinfection among other in the medical segment or industry.

MediPlas Driver

The MediPlas Driver is our driver for the ozone generator. It provides the necessary voltage output for ozone generation and can be used with the MediPlas Reactor as a component for desinfection among other in the medical segment or industry.

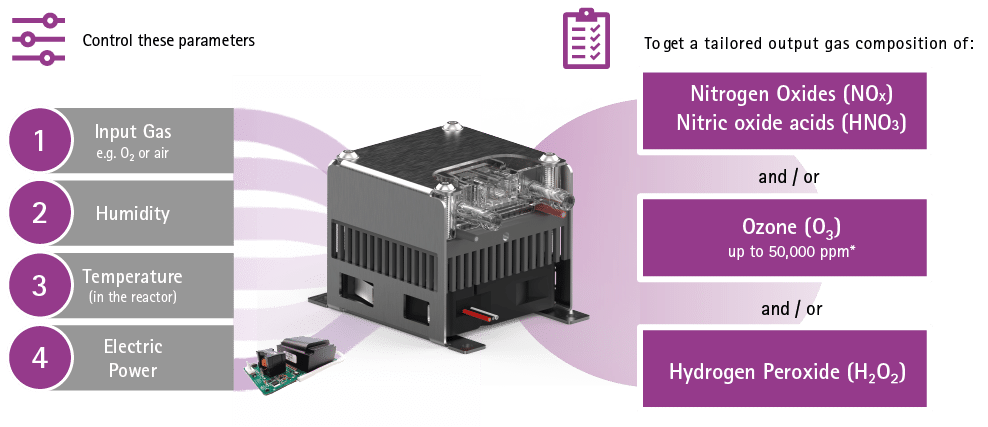

MediPlas operating principle

The MediPlas system consists of two components: the MediPlas Reactor and the MediPlas Driver. The reactor is the core component, which generates reactive oxygen and nitrogen species (RONS) using dielectric barrier discharge (DBD). The composition and concentrations of RONS in the resulting gas mixture depend on the type of gas supplied (e.g. composition, humidity, temperature), the electrical power supplied by the driver and the temperature in the reaction chamber.

MediPlas applications

The typical areas of application for this solution are:

– Food production and packaging

– Agricultural technology (seeds, seedlings)

– Pharmaceuticals

– Materials testing

– Air treatment

– Luxury food production and packaging

– Packaging of medical products

– Water treatment

– Wastewater treatment

– Odor neutralization

The medical applications of this solution are:

– Sterilization of internal medical systems

– Batch sterilization of sensitive medical devices in less time

– Use of highly reactive gases for local supply at the patient chair

Advantages of the MediPlas system

- Easy to integrate

- Low cost per cycle

- Avoids chemicals

- No consumables

- Short process time

- Low energy consumption

- Low temperature

- Medical grade

- High concentration

- Environment friendly

- Durable

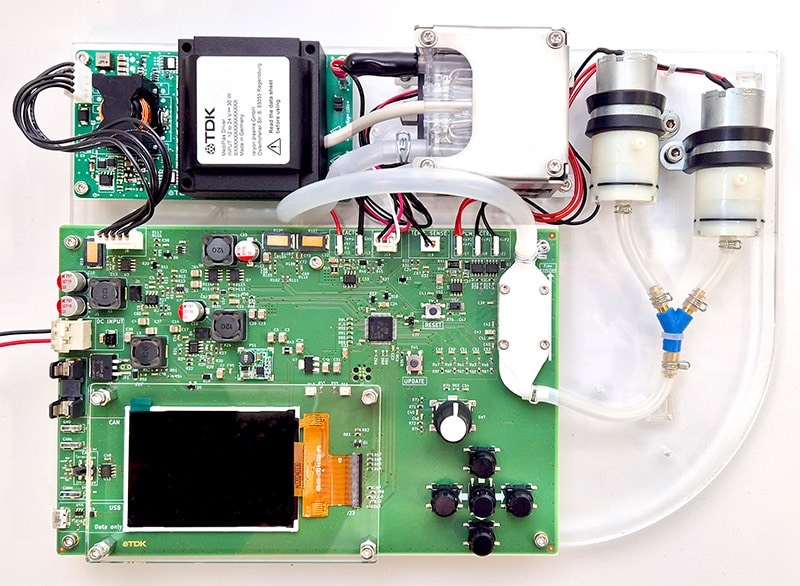

MediPlas Evaluation Kit

The MediPlas Evaluation Kit for system developers can be used to generate atmospheric pressure air plasma, from which gases with a variable composition of reactive oxygen and nitrogen species (RONS) can be generated.

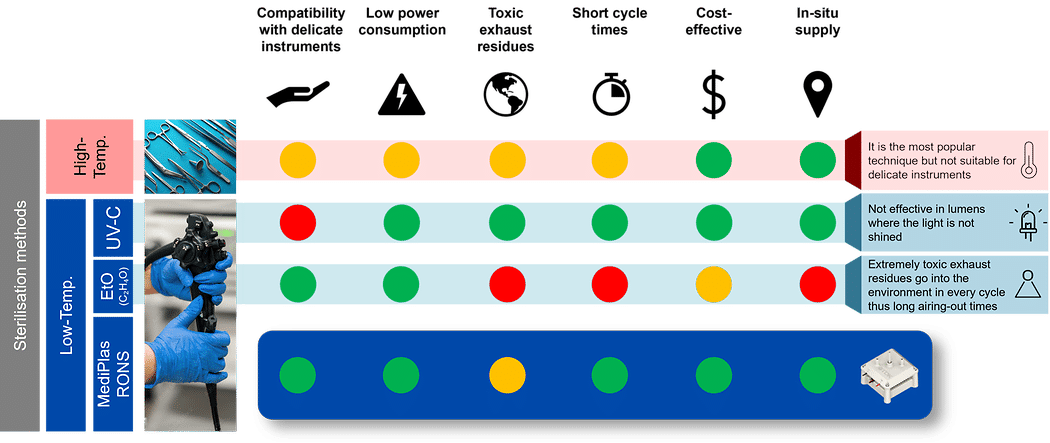

Comparison of common sterilization methods

With MediPlas, you can generate in-situ RONS, such as hydrogen peroxide, cost-effectively and in a fraction of the usual time. This makes it a genuine alternative to ethylene oxide (EtO).

Discover MediPlas in detail in our design guide!

Read our design guide and application description to learn how MediPlas from TDK can help you meet the challenges of disinfection.

The design guide discusses MediPlas and explains why this solution from TDK is superior. It combines effective disinfection with the efficient use of non-toxic, readily available gases at the inlet and the ability to provide various gases at the outlet.

Product ressources

Presentation

Defined Microbiological Contamination & Analysis of Surfaces After Treatment With Reactive Air by MediPlas.

Versuchs- und Lehranstalt für Brauerei in Berlin (VLB) e.V.

Download

Data sheets

MediPlas Reactor

Series/Type: V 1.0

Download

MediPlas Driver

Series/Type: V 4.0

Download

Library

Characterization for Ozone Production

MDPI Articel: Hybrid Dielectric Barrier Discharge Reactor

Artikel

Production of Reactive Oxygen-Nitrogen Species in Humid Air

MDPI Article: Hybrid Dielectric Barrier Discharge Reactor

Artikel

Order now

The MediPlas system at the Medical Technology Ireland 2025 trade fair

Exhibition stand

relyon plasma – a TDK group company

2nd floor, Booth 217

Date and venue

September 24–25, 2025

Galway Racecourse, Ireland

Get in contact

Would you like to learn more about MediPlas? Please briefly describe your application.

Please feel free to contact our experts here.