Atmospheric pressure plasma in solar thermal technology

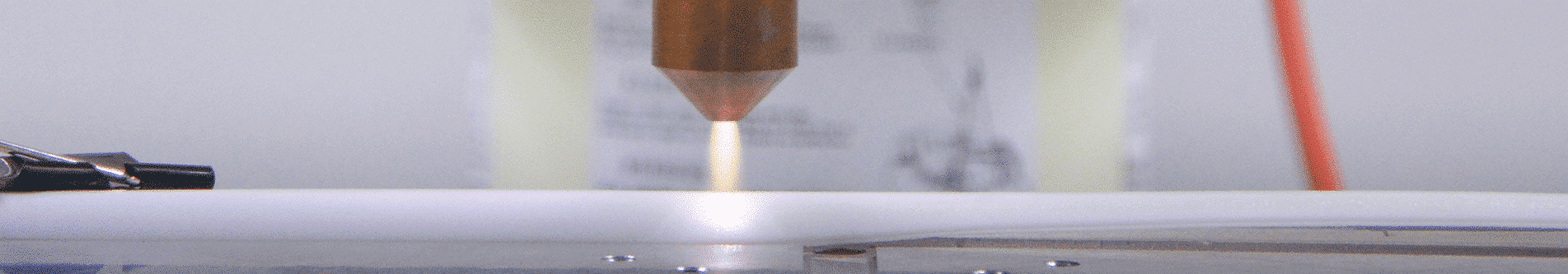

GREENoneTEC Solarindustrie GmbH from St. Veit in Austria uses plasma technology in the production of solar thermal collectors. The high-performance plasma system plasmabrush® PB3 is integrated into the automated surface pre-treatment of glass before bonding is integrated into the automated system. Günter Unterweger from the work preparation department reports below on his experiences with atmospheric pressure plasma in solar thermal technology.

Why relyon plasma?

GREENoneTEC chose reylon plasma because of the best price-performance ratio. In addition, the plasmabrush® PB3 technology could be integrated into our automated system very easily and without complications.

Due to the compactness of the plasmabrush® PB3 technology, the treatment of the bonding surfaces to increase the surface tension can also be very easily integrated into an automated system. This increases the process reliability for bonding many times over.

The surface tension is significantly higher with plasmabrush® PB3 technology than with treatment using a glass washing machine.

- Surface tension after glass washing machine: 44-48 mN/m

- Surface tension after plasma treatment: 66-72 mN/m

We are considering using the plasmabrush® PB3 technology also for the pre-treatment of bare aluminum profiles, which we currently clean in a time-consuming manner with stainless steel brushes.

About GREENoneTec

As the world’s largest thermal flat-plate collector manufacturer, GREENoneTEC has an annual production capacity of over 1.6 million m² of collector area. We offer the highest product quality with excellent delivery performance and reliability on eight highly automated robot production lines, we offer the highest product quality with excellent delivery performance and reliability – naturally Made in Austria, certified according to ISO 9001 and ISO 14001 and with 30 years of experience in the solar industry.