Webinar Series: Plasma in the medical industry

Due to the numerous trade fair postponements in medicine as well as in dental and medical technology, relyon plasma is organizing a new webinar series on plasma in the medical industry in order to present customers and interested parties with all the latest news on plasma in medical production, dental industry and implantology as well as medicine.

May 20, 2021 – Plasma in the production of medical devices

June 24, 2021 – Plasma in dental laboratory and implantology

July 29, 2021 – Plasma in medicine

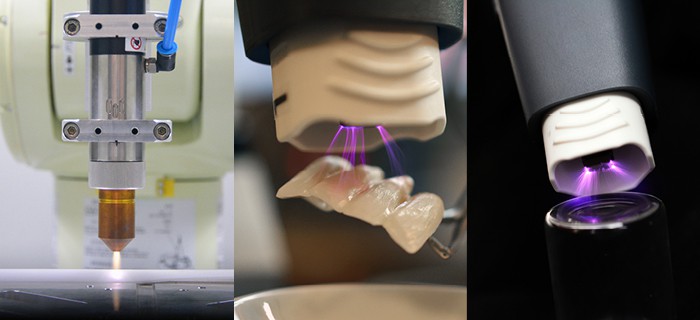

Plasma in medicine

In the webinar, plasma experts and physicians explain how atmospheric pressure plasma is used in medicine for disinfection, sterilization and skin treatment .

| Time | Topic | Speaker |

|---|---|---|

| 04:00 – 04:05 | Welcome and introduction | Simona Lerach – relyon plasma GmbH |

| 04:05 – 04:35 | Cold atmospheric pressure plasma devices in medicine – discharge types, regulatory challenges and development trends | Dr. Torsten Gerling – INP Greifswald |

| 04:35 – 05:05 | Cold plasma applied as a disinfection method | Dr. Stefan Nettesheim – relyon plasma GmbH |

| 05:05 – 05:30 | Skin Therapy Using Cold Atmospheric Plasma | Prof. Fei Tan – Shanghai East Hospital |

| 05:30 | Questions and Answers | All |

Cold atmospheric pressure plasma devices in medicine – discharge types, regulatory challenges and development trends – Dr. Torsten Gerling

Since about ten years, cold atmospheric pressure plasma sources (CAP) are on the market as medical devices. The number of companies providing CAPs depends on the definition of CAP itself and sums up to around three to five depending on literature. The uniqueness of CAP is the local generation of an effective cocktail, which was proven antimicrobial under lab conditions as well as inducing wound healing tracer signals. Here the existence of multiple different technologies on the market comes into play to extract the maximum usability of CAP for different treatment conditions due to different cocktail compositions depending on the discharge type and therefore device. The challenge to apply high voltage based devices under highly regulated safety restrictions as well as future trends of development will be discussed together with present and upcoming medical devices. The presentations aims to communicate an overview of the state of the art as well as motivate people to take part in the plasma medicine field.

Cold plasma applied as a disinfection method – Dr. Stefan Nettesheim

In the webinar Dr. Stefan Nettesheim discuss how temperature stable and chemically resistant germs can be killed with high efficacy by practical application of cold non-equilibrium plasma. Therefore he will present different concepts starting with the handheld device up to the integration kit.

The webinars take place via the GoToMeeting platform and participation is free of charge.

Skin Therapy Using Cold Atmospheric Plasma – Prof. Fei Tan

Cold atmospheric plasma (CAP)-based plasma medicine is an emerging interdisciplinary field exemplified by its potentials in several medical and surgical specialties. In addition, our recent study has demonstrated CAP’s multimodal effect for multi-tissue regeneration. One of the most intensively studied specialties of plasma medicine is dermatology, partially because skin is the largest and most superficial organ in the human body, which makes plasma treatment relatively easy. Here, we present the first relevant review that is comprehensive, up-to-date, disease-specific, and bridging the gap between biotechnology and clinical practice.

Plasma in the dental laboratory and implantology

In the webinar, dental technicians and implantologists explain live in which process steps plasma is used in the dental industry and how the patient benefits from the use of plasma technology.

| Time | Topic | Speaker |

|---|---|---|

| 04:00 – 04:05 | Welcome and introduction | Simona Lerach – relyon plasma GmbH |

| 04:05 – 04:35 | Cold plasma in dental technology | Moataz Bayadse – University Medical Center Mainz |

| 04:35 – 05:05 | Investigation of plasma effects on implants | Dr. Sebastian Schaubach – dataPhysics Instruments |

| 05:05 – 05:30 | Case Study: Plasma treatment at the dentist | Florian Freund – relyon plasma GmbH |

| 05:30 | Questions and Answers | All |

Cold plasma in dental technology – Moataz Bayadse – University of Mainz

This lecture describes the introduction of cold plasma and its diverse indications in dentistry. The benefits of cold plasma application can be observed in various fields of study like dental surgery, dental prosthetics, hygiene and sterilization. Aim of this lecture is to give an overview about potential clinical applications of cold plasma in dentistry and show in vitro data on the promising potential of activation of dental materials.

Investigation of plasma effects on challenging surfaces – a case study on medical implants – Dr. Sebastian Schaubach – DataPhysics Instruments

To characterize the surface chemical properties of a material, contact angle measurements and calculated surface free energies have proven to be reliable parameters over many years. For example, the effect of plasma treatment on a wide variety of surfaces can be quantified. But what do you do if the surface to be characterized is very finely structured or exceeds the measurement capabilities of classical optical contact angle measurement? In our webinar we would like to show you how special picoliter dispensing systems can be used to measure the contact angle on plasma-needled dental implants with a very fine structure. Furthermore, we will show you the concept of imaginary contact angles with which hyperhydrophilic surfaces can also be quantitatively investigated with regard to wettability.

Plasma treatment at the dentist – Florian Freund – relyon plasma GmbH

While the cold plasma handheld piezobrush is already being used in dentistry on healing caps, implants and protheses of various materials, the new relyon plasma implaPrep concept is designed especially for the safe and reproducible treatment of titanium implants. A prototype of this new device will be presented along with different use cases of cold plasma in the dental office including the experiences of Dr. Reichermeier in Regen, Germany and Dr. Schweiger in Füssen, Germany.

Plasma in the production of medical devices

In the webinar, experts from plasma and production technology will use practical examples to explain how plasma technology is used in the production of medical products for process and quality optimization.

Introduction to the topic of plasma in medical technology

In medical technology, particularly high demands are placed on the properties of the materials used. This is often at the expense of processability, especially with regard to adhesion processes such as bonding and printing. However, it is precisely these processes that have become indispensable in modern production and are only possible through pre-treatment. Classically, toxic primers are often used here, but increasingly cold atmospheric pressure plasma is also being used for surface activation.

Cold atmospheric pressure plasma is a partially charged gas that has two main effects on surfaces. Firstly, it is able to remove organic impurities from surfaces through fine cleaning. Secondly, plastics in particular can be functionalised so that they wet better and adhesion-controlled subsequent processes are thus possible. These processes take place at the atomic level without changing the optical and bulk properties.

The most common method of plasma treatment is based on PAA® technology, in which plasma is ignited via a pulsed arc and transferred to the surface by a jet. With this method, there are a variety of applications that are also particularly relevant in the medical technology industry, especially when it comes to a high degree of line speed and automation.

Optimizing production processes in medical technology with cold PDD® plasma

The quality of adhesion processes such as bonding, sealing or printing has a decisive impact on the further processing, quality and durability of medical products. The materials used, such as special plastics, are often difficult to wet and usually cannot do without appropriate pre-treatment. Piezo Direct Discharge or PDD® technology provides a cold, atmospheric plasma with which the functional surfaces of a wide variety of materials can be activated either manually or automatically. This allows easy and cost-effective optimization of the subsequent adhesion process without the need for harmful wet chemistry or safety-critical flame treatment. The application areas and advantages of this technology will be demonstrated using various practical application examples.

If you have any questions about the event or about plasma in general, please feel free to contact us at any time:

E-mail: info@relyon-plasma.com

Phone: + 49 941 60098-0

We are already looking forward to welcoming you virtually in Regensburg!