Bonding of plasma-modified polyether ether ketone (PEEK) for dental applications

The Laboratory for Chemistry and Surface Modification at the University of Applied Sciences Osnabrück has been working on the effect of the piezobrush® PZ3 on the plastic material polyether ether ketone (PEEK), which is widely used in dentistry, as part of the beta test phase of the cold plasma handheld device.

Improved bonding quality of possible PEEK/PEEK joints in components for (dental) implants is the motivation for this work. In the course of the investigations at the Osnabrück University of Applied Sciences, the Marius Behnecke compared different pre-treatment methods for improving adhesion: a conventional grinding process, low-pressure plasma treatment and plasma treatment with the piezobrush® PZ3 handheld device. It was observed that both plasma treatments were superior to grinding. In the numerous analysis methods used, the manual plasma treatment with the piezobrush® PZ3 was comparable to that in the low-pressure chamber. This makes the PDD® plasma (“Piezo Direct Discharge”) of the piezobrush® PZ3 a highly efficient and flexible alternative to conventional low-pressure plasma processes.

Execution of experiments

A 0.6 mm thick PEEK film with the trade name evonik VESTAKEEP 4000g serves as substrate material. The dimensions of the samples here are 60 x 100 mm. First, the surfaces are cleaned with isopropanol and then placed in an ultrasonic bath for one minute. After wiping three times with a 1:1 mixture of isopropanol and n-heptane, the samples are fed to the various pre-treatments. The three investigated modifications are:

- Sanding the surface with 240 grain sandpaper

- Low pressure plasma treatment (air, 0.2 mbar, 1 minute, 100 W)

- PDD plasma of piezobrush® PZ3 (air, atmospheric pressure, 1 minute, 5 W)

This is followed by the adhesive application of methyl methacrylate-based Weicon RK-7300 with an adhesive layer thickness of 0.25 mm on 5 mm width and curing for 24 h at 30°C.

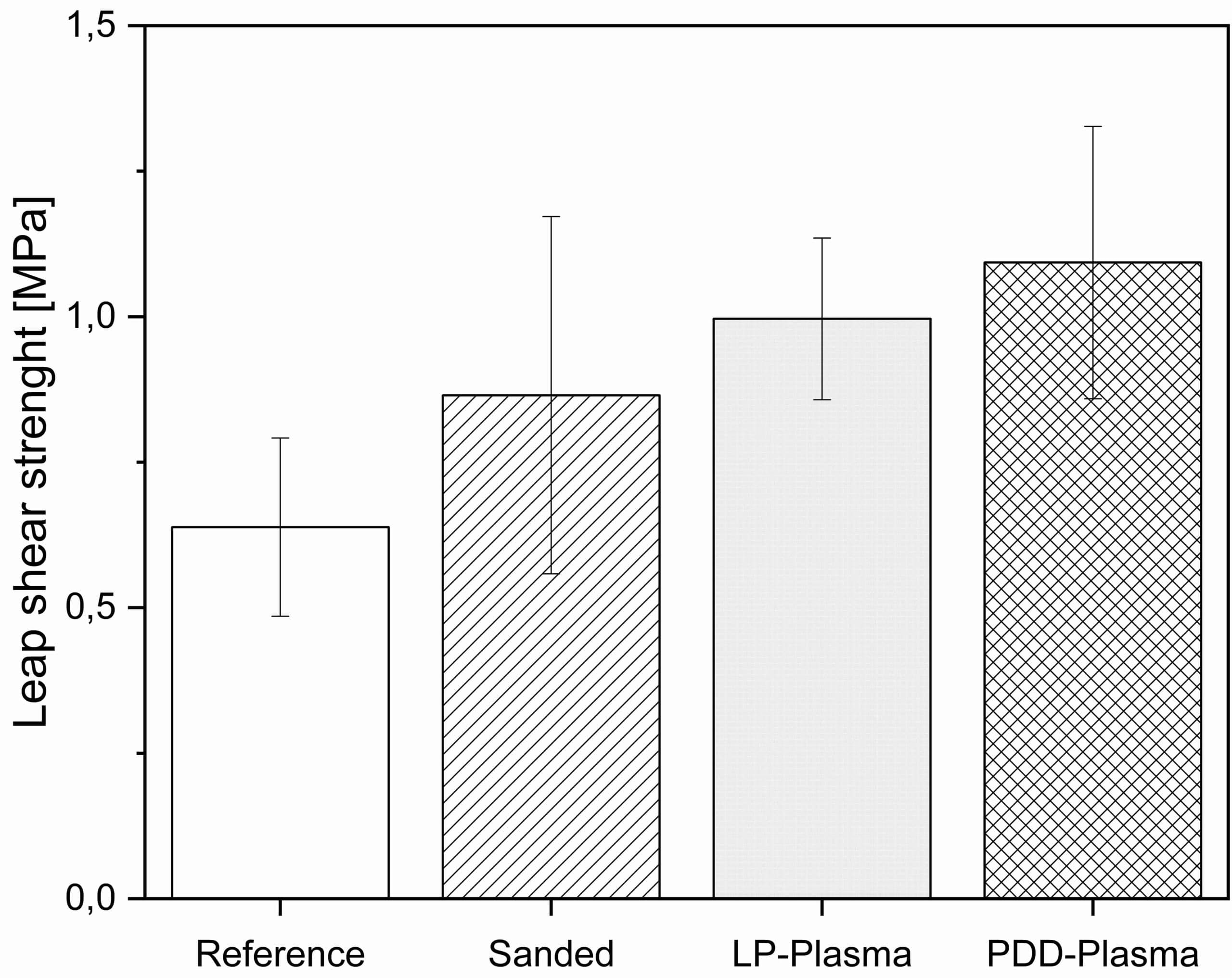

Tensile shear tests

The quality of the adhesive bond is measured by tensile shear tests according to DIN 1465. Only the sample geometry deviates from the standard, the adhesive surface is DIN-compliant. The test speed on the ZwickRoell tensile machine is 1 mm/s. The tensile shear strength is significantly increased by all three pre-treatment methods compared to the untreated reference (see Fig. 1). Grinding leads to the greatest dispersion of the results. In contrast, treatment in the low-pressure plasma chamber (LP plasma, “low pressure”) results in the lowest standard deviation. This, as well as the plasma treatment with the PDD plasma of the piezobrush® PZ3, leads to a noticeable increase in the tensile force, since the respective standard deviations do not overlap with those of the reference sample. Overall, it can be seen that the manual pre-treatment with the piezobrush® PZ3 achieves tensile shear strengths comparable to low pressure plasma treatment. Both plasma treatments are superior to the grinding of the substrates.

Contact angle measurement

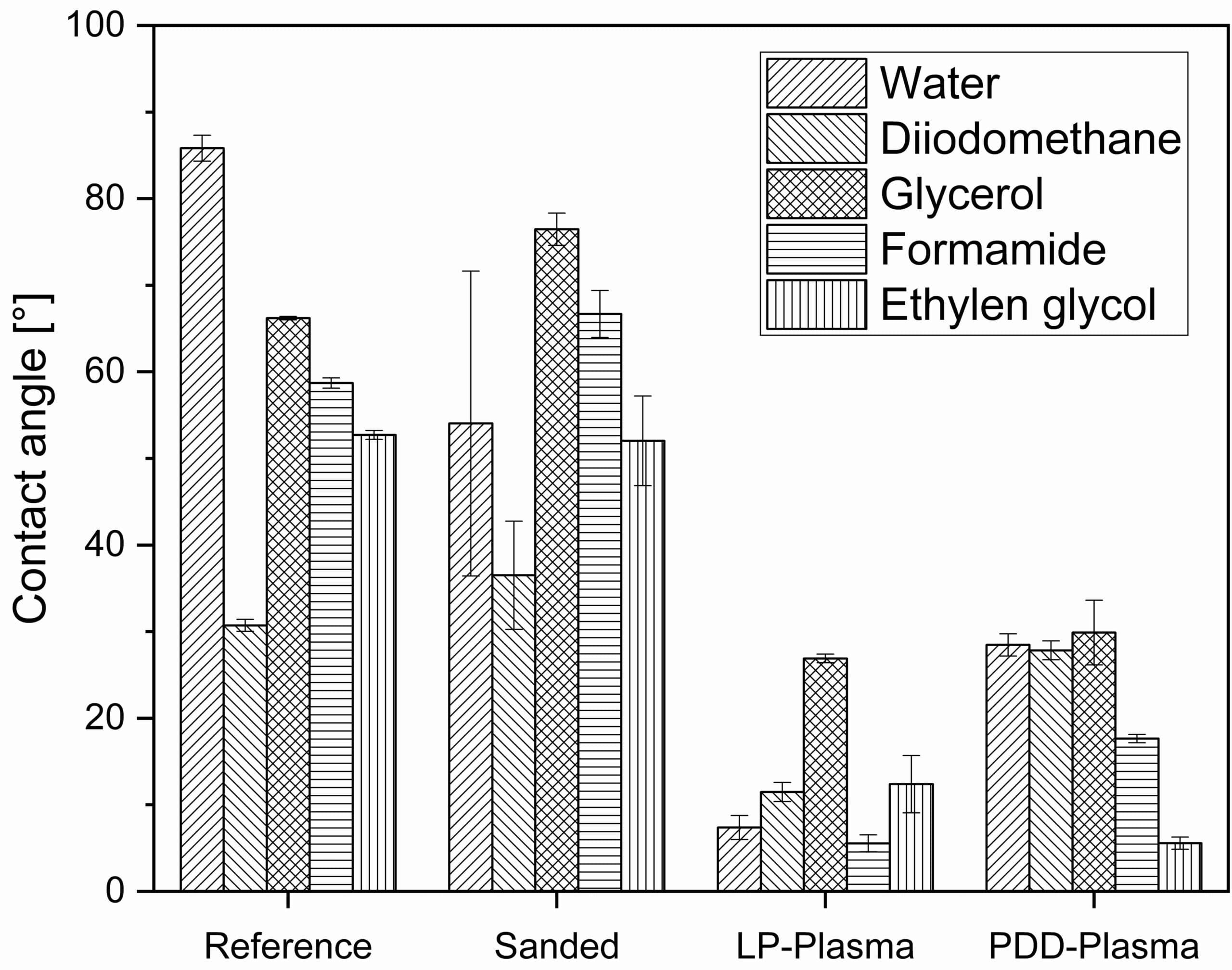

To better understand the results of the tensile tests, the surface is characterized before and after the different pre-treatments. For this purpose, contact angle measurements are performed with five different liquids: water, diiodomethane, formamide, ethylene glycol and glycerol. The evaluation is carried out according to two different methods:

- Owens-Wendt-Rabel and Kaelble method (OWRK method): division of the free surface energy into polar and disperse fractions

- Berger method: Determination of an acidity parameter to characterize the acidic or basic properties of the surface

The contact angles of the five test liquids are each determined using the “Sessile Drop” method (resting drop) on the OCA20 from the manufacturer DataPhysics Instruments GmbH (Filderstadt, Germany).

All modifications lead to a reduction of the contact angles and thus to a better wettability compared to the reference (see Fig. 2). Again, the results of the ground sample show the highest scattering. Both the plasma treatment in the low-pressure chamber and the plasma treatment with the piezobrush® PZ3 handheld device significantly reduce the contact angle of all test liquids. Here, the low-pressure plasma (LP plasma) has the greatest influence on the contact angle of the test liquids.

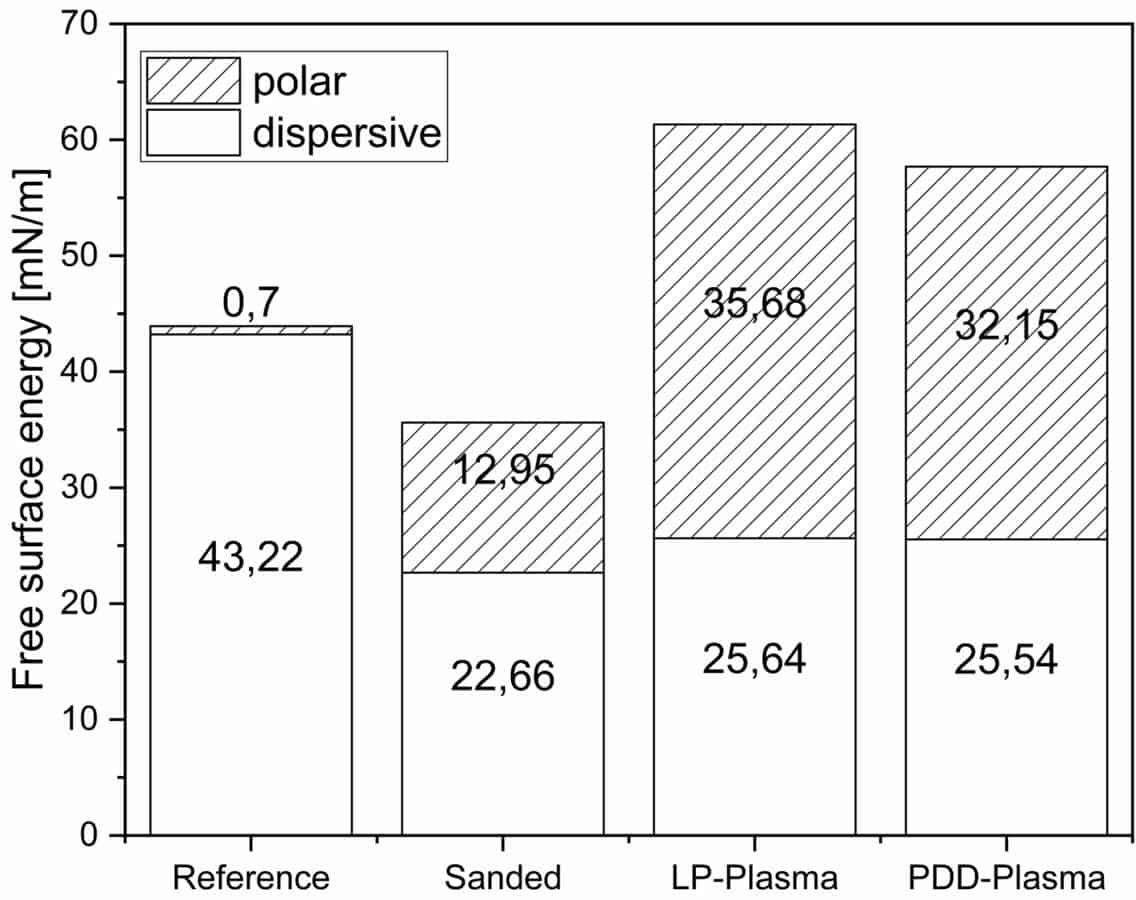

Surface energy

From the results of the contact angle measurement, the surface energy is now determined according to the OWRK method. The evaluation was performed using SCA20 software from the manufacturer dataphysics (Filderstadt, Germany). Grinding the surface leads to a lower total energy, but with higher polar fractions (see Fig. 3). Both the plasma treatment in low pressure and the plasma treatment with the piezobrush® PZ3 handheld unit lead to significantly increased surface energies on the plasma-modified PEEK substrate with strongly increased polar fractions. The low-pressure plasma generates slightly higher polar fractions, while the disperse fractions are at the same level for both plasma technologies.

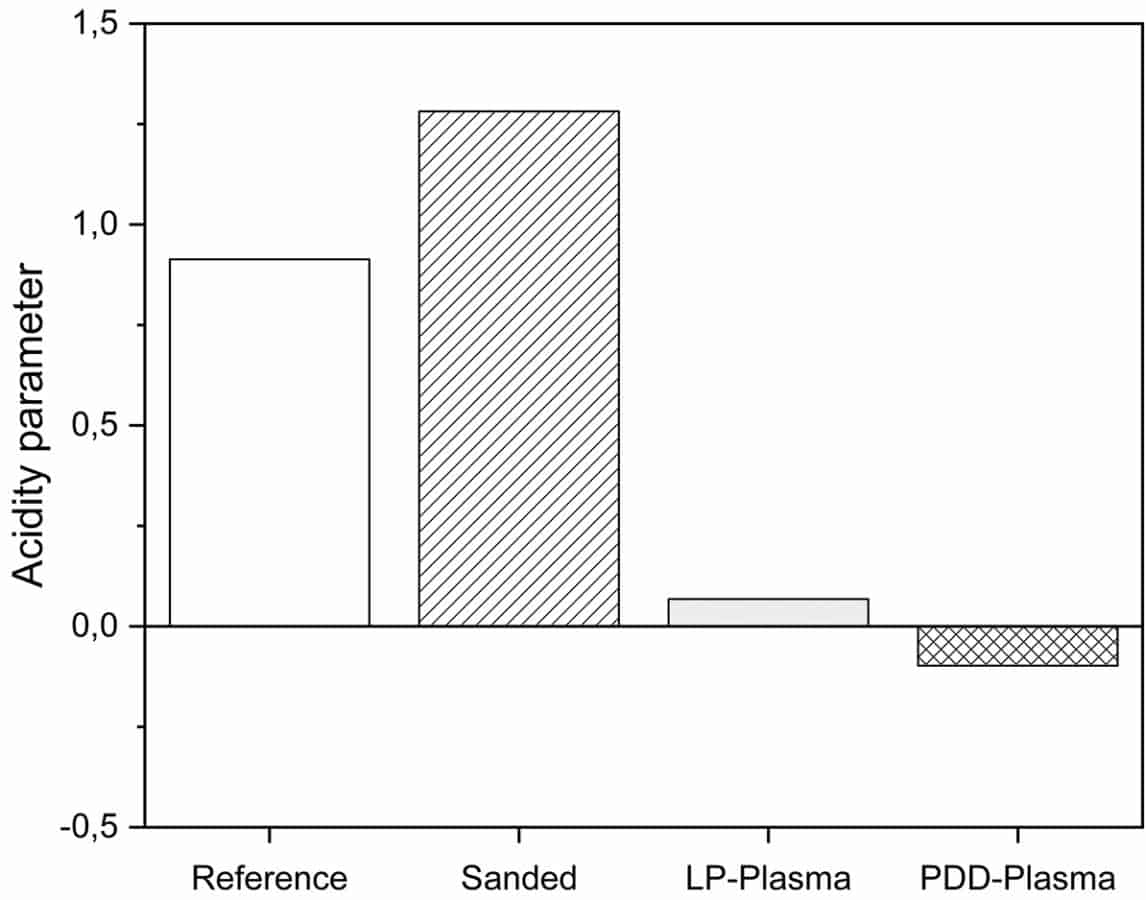

Acidity of the surfaces

Also based on the contact angle measurements, the acidity parameters of the different samples are now determined. The evaluation is based on Berger, E. J., J. Adhes. Sci. and Techno. 5, 373 – 391 (1990). The unmodified PEEK substrate has a slightly acidic character, as the positive value in Fig. 4 shows. Grinding of the surface seems to promote this behavior, but the method is not suitable for strongly varying roughness. Acidity is reduced both by low-pressure plasma treatment and by treatment with the piezobrush® PZ3. In the latter case, the PDD plasma even produces a surface with basic properties.

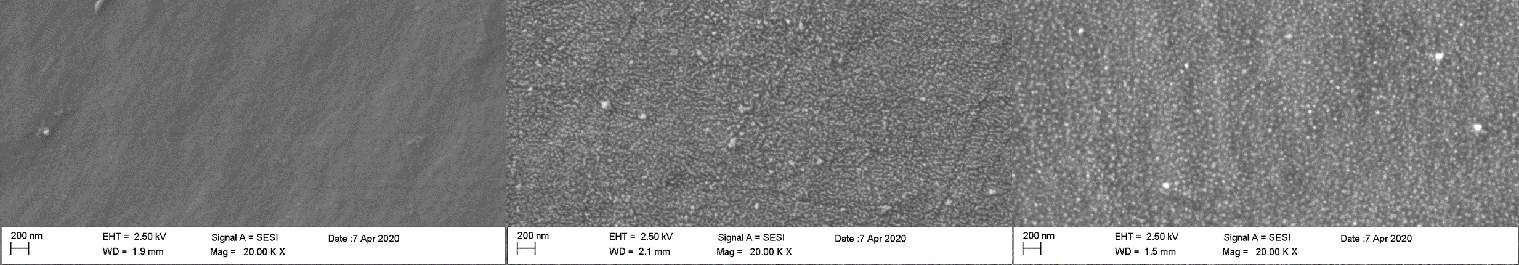

Scanning electron and atomic force microscopy

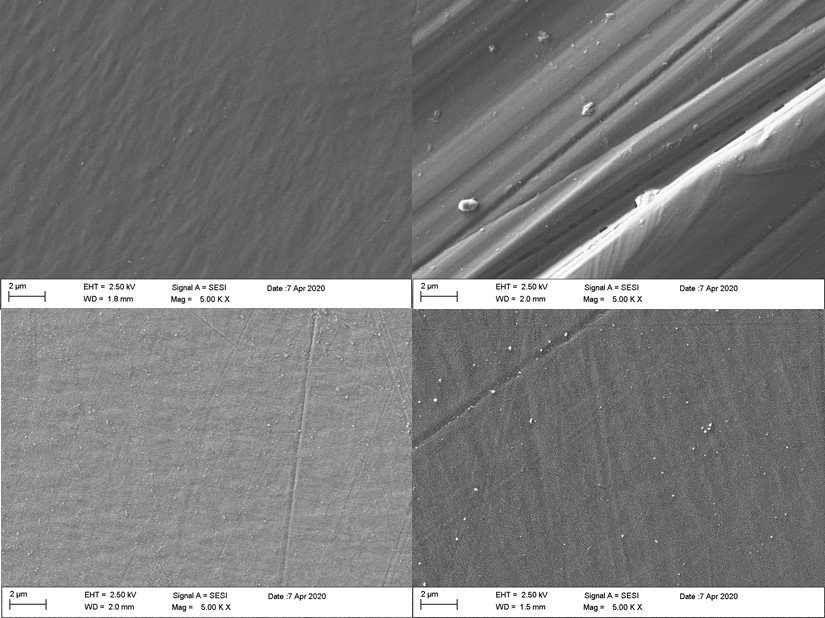

In order to assess the surface quality of the various samples, they are examined under a scanning electron microscope. The images are taken using the AURIGA cross-beam scanning electron microscope from Carl Zeiss AG (Oberkochen, Germany).

Fig. 5 clearly shows that at five thousand times magnification there is hardly any change in the plasma-treated surfaces, in contrast to the sample after the grinding process.

At a magnification of twenty thousand times, a change in the structure of the PEEK surface after the plasma processes can be seen. Here the surface condition is very similar after treatment with low-pressure plasma and with the piezobrush® PZ3.

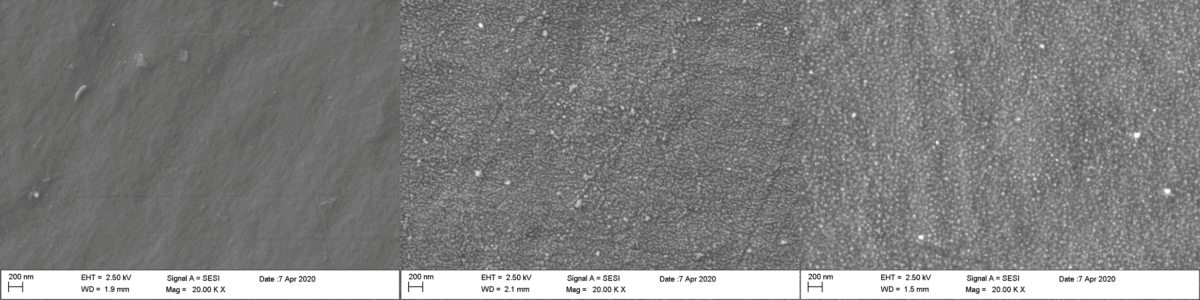

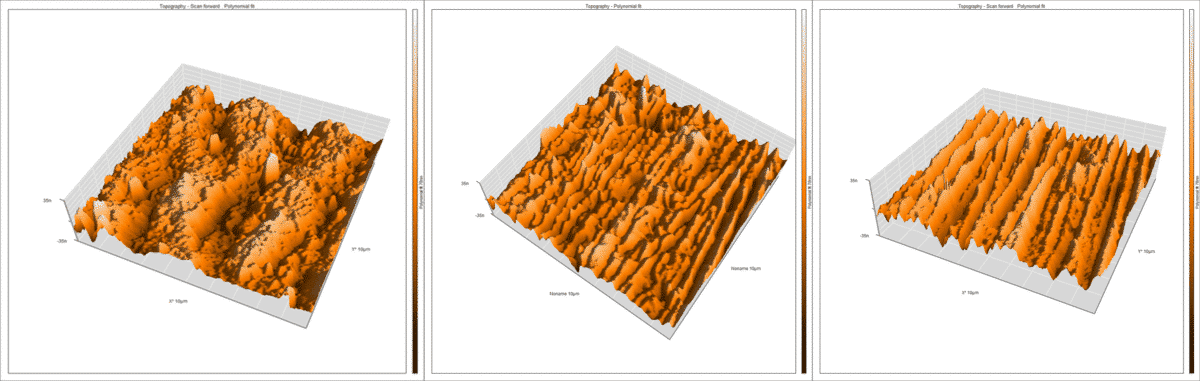

The extent to which the topography of the samples differs can be determined using atomic force microscopy. Here, the ground sample cannot be measured due to the high surface roughness. The untreated surface of the PEEK film and the respective surfaces after the plasma treatments are measured using the contact mode of the Easyscan2 atomic force microscope from Nanosurf AG (Liestal, Switzerland).

The surface topography of the untreated sample shown on the left in Fig. 7 has a surface roughness Sa= 6.7 nm. After treatment of the PEEK film in low-pressure plasma, this value increases to Sa= 7.4 nm and is thus comparable to that after treatment with the piezobrush® PZ3 with Sa= 7.1 nm.

Conclusion

On the PEEK surface under investigation (evonik VESTAKEEP), plasma treatments lead to improved adhesion, even compared with mechanical grinding of the surface. Even by high-resolution scanning electron microscopy, only a nanostructuring of the surface can be detected. The micro- and macroscopic topography is not affected, in contrast to mechanical surface treatment, i.e. grinding. The method of contact angle measurement shows comparable results after low-pressure plasma treatment and treatment with the piezobrush® PZ3 for surface energy and acidity parameters. For both plasma processes a treatment time of one minute was chosen in each case. The plasma power of the low-pressure chamber is 100 W, that of the piezobrush® PZ3 can be quantified to the 5 W input power of the piezoelectric transformer CeraPlas™. While the chamber for the low-pressure plasma has to be pumped out and ventilated after the process, the atmospheric plasma of the piezobrush® PZ3 does not require an external gas supply due to the integrated fan. This makes the handheld unit a highly efficient, cost-effective and flexible alternative for plasma treatment of components, for example in dental technology.