Plasma treatment of polymer base plates

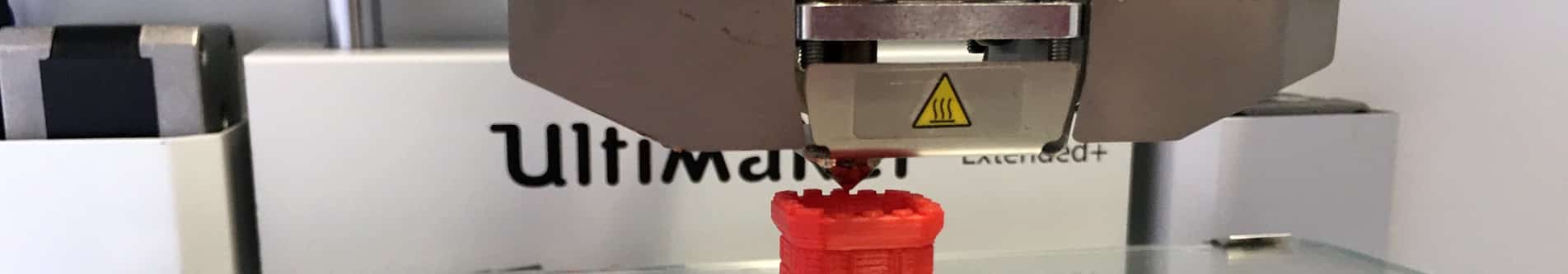

At the TH Lübeck, a plasma treatment of polymer base plates is carried out before 3D printing in order to achieve good adhesion.

In recent years, 3D printing has become increasingly important and is now established in manufacturing technology. Due to the increased importance for industrial and private customers, the demands on quality, material variety and robustness are now increasing. For years, the Regensburg-based company relyon plasma GmbH, a subsidiary of the TDK Group, has been researching plasma activation in this application field. Above all, the production of large and complex components poses a challenge. These can only be manufactured as individual parts and then have to be bonded. This is where plasma technology is used to get a better adhesion and thus a strong bond between the individual parts.

Key Word Search