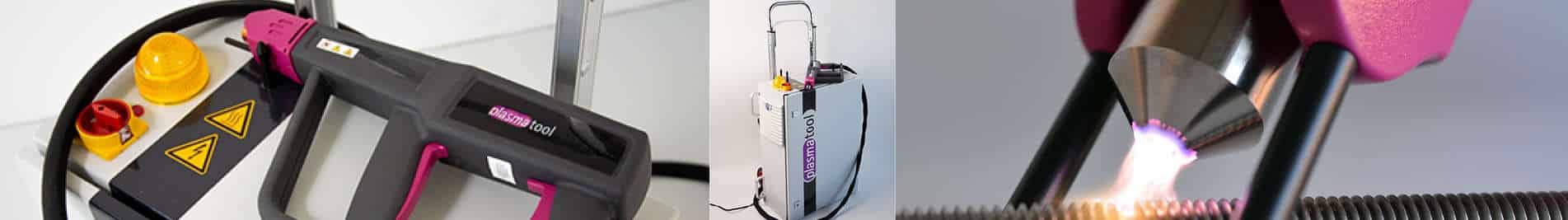

PlasmaTool handheld device

The high-efficient tool for flexible and easy surface treatment in industrial environments.

With the PlasmaTool, surfaces on a wide variety of materials can be selectively optimized before bonding or printing in order to replace primers or other pre-treatments. Significantly higher wettability and adhesive forces can thus be easily achieved even on workpieces that cannot be processed by machine due to their size or mobility. Since the PlasmaTool only requires a 230 V power supply, the device can be used anywhere. The trolley design makes it easy to use the PlasmaTool in different locations. Two-handed operation and a signal lamp protect and warn the operators and third parties. The handling of the PlasmaTool is optimized for easy usage and maximum operator´s safety. No external gas supply has to be present. A completely autonomous air supply is integrated inside the device. The operator is independent of any compressed air supply.

Field of application

- Railway construction

- Aircraft / caravan construction

- Treatment of very large components

- Automotive

- Handcraft

Fields of application

- Removal of rust

- Pre-treatment prior to the painting or varnishing process

- Paint removal during repairs

- Plasmacleaning

- Plasmaactivation

- Restoration

- Maintenaince

- Interior constructions

Advantages

- No size limitation of the parts to be treated

- High mobility

- Different processes / substrates / geometries

- No PLC necessary

- Stand-Alone unit, no compressed air or mass flow control required

- Only power outlet needed

- Single person handling thanks to trolley design

- Two-handed operation and signal lamp for advanced safety

- Robust and easy to use

Application examples

Plasmatool at Roding Automobile – passion unites

Roding Automobile GmbH is an internationally active technology company in the field of lightweight construction and electromobility. Read how they use plasmatechnology.

PlasmaTool in our Online Shop

-

Rental unit PlasmaTool1.000,00 € / 29 days

zzgl. Versandkosten

-

PlasmaTool13.900,00 €

zzgl. Versandkosten

Technical Data

- Electrical connection 220 – 240 V AC, 50 – 60 Hz

- Max. input current 6 A

- Power consumption 1.300 W

- Weight approx. 60 kg.

- Plasma temperature few hundred – less than thousand degrees

- Typical treatment distance 5 – 20mm

- Typical treatment width 10 – 25mm

- Measurements 800 mm x 540 mm x 430 mm

- Sound pressure level <60 dB (A) at a distance of 1 meter

FAQ

Downloads

| Title | Language | Download |

|---|---|---|

| PlasmaTool Flyer | DE | Flyer |

| PlasmaTool Flyer | EN | Flyer |

| PlasmaTool Betriebsanleitung | DE | Betriebsanleitung |

| PlasmaTool Operating instructions | EN | Operating instructions |

| PlasmaTool Manual de instrucciones | ES | Manual de instrucciones |

| PlasmaTool Notice d´ utilisation | FR | Manuel d’instructions |