Real-time analysis of atmospheric plasma processes

By measuring its dynamic electrical curve, atmospheric plasma processes can be monitored and controlled. No additional sensors are needed as a close real-time analysis of the measured current and voltage values already reveals a multitude of process information.

Intelligent process control

The most intelligent way for predictive maintenance and avoiding machine downtime is having an exact knowledge of the process flow as well as all relevant parameters.

Maintenance planning in particular faces the daily challenge of ensuring maximum machine availability while at the same time minimizing material consumption for maintenance and repairs. This is a requirement which most existing maintenance concepts cannot meet. The exit nozzles used in atmospheric plasma processes have a limited lifespan. Either, the nozzles are changed prophylactically at fixed intervals, accepting the fact that only about 70% of their potential life cycle is exploited, or the process is continued up to the point when it becomes apparent that the desired effect begins to lack in quality. In many cases, the latter is not acceptable as it involves the risk of producing substandard products or rejects.

Of course there are other conditions which influence process stability. For instance, fluctuations or faults in the system can be caused by the facility’s gas/compressed air supply system.

Our network capability solution

An integrated process network, often referred to using the term “Industry 4.0“, is one of the keys to success. Network capability as such is not effective without the specific ability of recognizing relevant patterns in the primary process data and consequently triggering events (e. g. maintenance or readjustments).

Our solution for predictive maintenance opens up new ways of recording the current state of your plasma process in real time, without the use of additional sensors potentially susceptible to faults. The data is screened for patterns which point to possible interferences. Any looming failures or malfunctions can be detected in advance and corrective measures can be planned and initiated in the best way possible in order to avoid unforeseen downtime and optimize the dedication of personnel and resources.

If the information is integrated into an MES (Manufacturing Execution System), there is a multitude of possibilities when it comes to maintenance planning, quality assurance and constant process documentation.

The plasma system

Atmospheric plasmas have conquered many fields of industrial application. Relyon Plasma Ltd. develop especially compact and durable plasma generators equipped with nozzles. The use of a unipolar pulsed high voltage power supply and a vortex flow inside the nozzle keeps the electric arc from stabilizing at a “hot spot“.

The electric arc rotates inside the combustion chamber at a high frequency. In spite of the high power density, the nozzle warms only slightly and the electrodes hardly erode at all. The plasma temperature can be freely adjusted over a wide range.

High voltage supply PS2000 in a robust 19inch industrial standard design, complete with high voltage cable (10m) and Plasmabrush® plasma generator for atmospheric plasma processes

Our innovative approach in process control is to monitor the electric impedance of the plasma discharge precisely and with high time resolution. The required measuring technology is already integrated into the high voltage supply PS2000 by default. The data collected is processed internally and provided digitally on a bus, without any additional sensors being necessary. The high voltage supply unit PS2000 has consciously been designed to be compatible with the independent CanOpen industrial standard, which facilitates extremely secure communication in even the roughest industrial environment. A great number of sensors also use this CanOpen standard. All industrial controls commonly used worldwide provide the according interfaces, which come pre-integrated in modern versions.

Our basic communications package for USB bus including converter, CAN cable, terminating resistor and software on USB stick

For direct connection with any common PC, there is a compact USB/CAN interface and our compatible software PlasmaControl for control and visualization. Data points from the dynamic electrical map can be recorded with high temporal resolution and be transferred to the PC. Naturally, this communication can also be established with any other commonly used industry solution, PLC or IPC.

The following typical process parameters greatly influence the effect which atmospheric plasma jets have on the object treated:

- working distance

- composition of the process gases

- volume flow or pre-pressure of the process gas

- age condition of the nozzle

- conductivity of the substrate

- setting of the plasma output

The super ordinate system determines a few other parameters such as the speed or the trajectory of the plasma nozzle relative to the substrate.

Variations in all of these influential parameters can be accounted for by the precise, time-resolved measuring of power and voltage in the control circuits of the power supply (PS2000). The atmospheric plasma jet can thus be viewed as a probe or sensor which is highly sensitive to any changes in the process conditions. In the simplest case, warning signals can be triggered if the predefined map range is exceeded.

Below, a few typical applications are described.

Change in the compressed air supply

Any variation in the plasma generator’s air flow changes the flow conditions and the burning behavior. In practice, it is always possible to find a work area which allows the process to run smoothly and where small fluctuations do not matter. However, unexpected short-term malfunctions or a steady drift (change in pre-pressure) may cause the predefined work area to be left, or signs of a systematic fault in the compressed air supply can become apparent. Even if the burning map of the plasma jet remains constant to the bare eye, a fluctuation in the air throughput of as little as 1% can already be identified clearly in the electrical parameters.

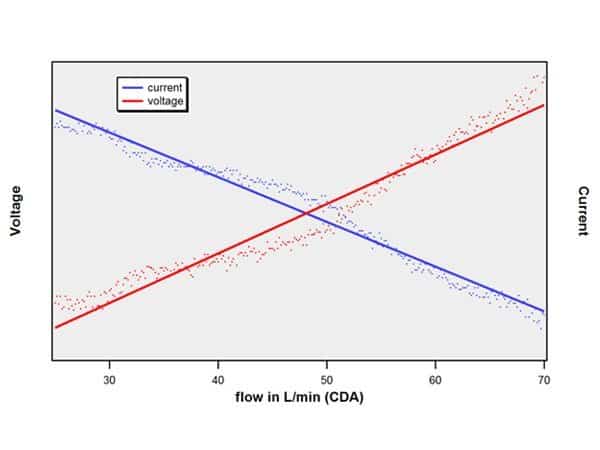

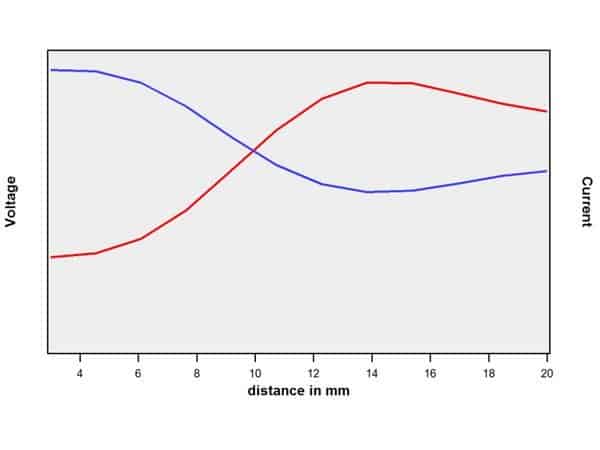

Over a time span of several hours, stochastic modifications were made in the air supply and the U/I parameters were read out of the PS2000. With rising air flow, the working voltage increases while the operating current decreases. Under typical operating conditions, this relation is linear in good approximation.

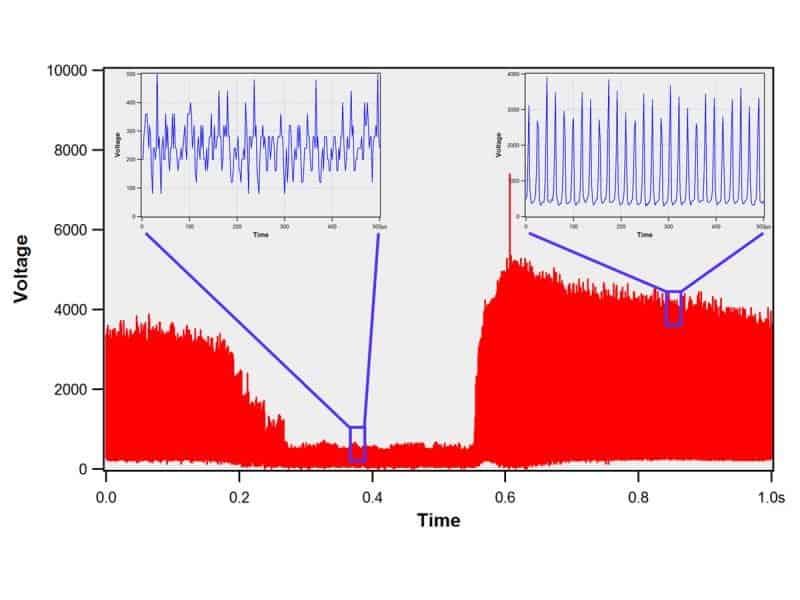

The example of a momentary dropout of the compressed air supply (e. g. caused by a brief squashing of the supply line) makes it apparent that the electrical response function shows a microstructure characteristic of a collapsed vortex flow. A fluctuation in the flow ratios causes the medium voltage level to slump down and the electric arc burns in an unstable way with stochastically variable length and intensity. This interruption of the electric arc can be delineated with a time resolution of one millisecond. In practice, it is not desirable for a system to immediately shut down when there is a very brief fluctuation. However, it is possible that in this short time interval of technical malfunction the products have been treated incompletely and an error message should be relayed to the superordinate system.

A brief drop in air supply of less than half a second causes an instabile transient in the plasma’s burning behavior. The disruption is short enough for the system to not shut down and keep running steadily after the dropout.

Aging process of the nozzle

The nozzle’s aging process is primarily driven by an oxidative erosion of the cathode. On the outside, the nozzles discolor and show signs of erosion at the nozzle exit. Even when there is visible outward wear, such a nozzle can still keep running steadily for a long time and fulfill its original function, e. g. activation performance. The practical question therefore is when the nozzle will have to be replaced and how the system will request this maintenance.

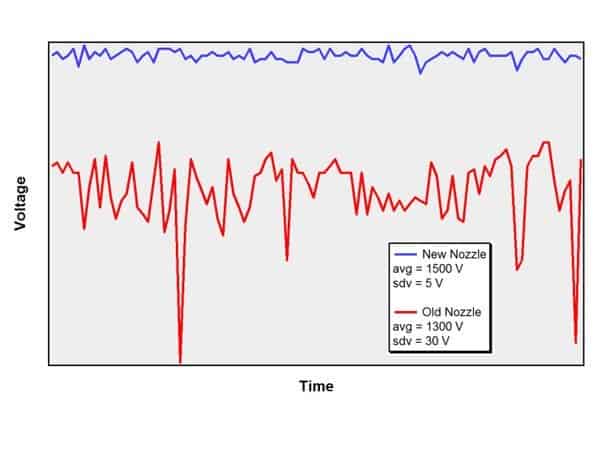

Interestingly, all aging processes show a similar pattern in which the original working voltage decreases and consequently, in order to maintain the “constant output“ mode, the operating current increases accordingly. While neither an absolute voltage level nor the operating current are dependable indicators of a nozzle’s wear, it is the fluctuations in electric current and voltage that reliably reveal irregular burning behavior. Changes in burning geometry and an unstable operating behavior are reflected in an increased standard deviation in the time-resolved measurements of current and voltage values. This information can trigger a proactive nozzle exchange without dismantling and visual inspection.

Comparison of a nozzle after 200 hours of operating time with a nozzle, which has reached its wear limit. Both nozzles still provide good activation performance and run on identical electrical power. The worn nozzle shows first signs of flickering and a change in its burning geometry by displaying a sixfold electrical fluctuation margin in its working voltage.

Changes in the process gas composition

Not all applications use compressed air, but process gases such as nitrogen, CO2, oxygen or hydrogenous forming gas are also employed. Surfaces sensitive to oxidation, for instance, should principally be treated with inert nitrogen. Even the smallest amounts of oxygen might interfere with the process and substantially alter the plasma chemistry.

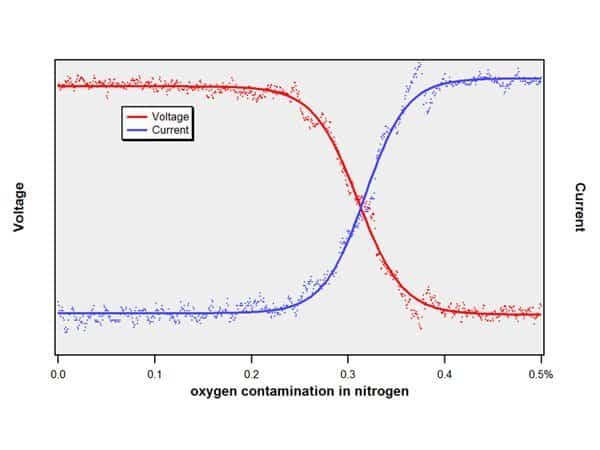

The U/I parameter reacts very sensitively to the gas composition. In the experiment presented, in which slight amounts of oxygen were added to a nitrogen carrier gas, even 0.1% of oxygen were reliably detected. This proves the sensitivity of the method to be entirely satisfactory for practical applications using mixed gases.

A change in the process gas mixture can occur intentionally or be the result of a fault, such as as a leak or a mixing component running empty.

Oxygen is gradually added to nitrogen carrier gas until an oxygen level of 0.5% is reached. Even a modification of 0.1% significantly alters the characteristic U/I curve.

Changes in the substrate characteristics

In a production process, the nozzle is typically guided over the product to be treated along a predefined course. If a product, e. g. an electronic assembly, is composed of various areas with differing ohmic and dielectric characteristics, these changes will be reflected in the electrical parameters of the high frequency plasma process. If the plasma flame is to be used as a dielectric “probe“, the pulse frequency may be varied in order to perform a contactless (that is, purely electrical) scan of the material.

A stable production process can thus be reliably facilitated, e.g. by detecting a missing product or wrong product on the conveyor.

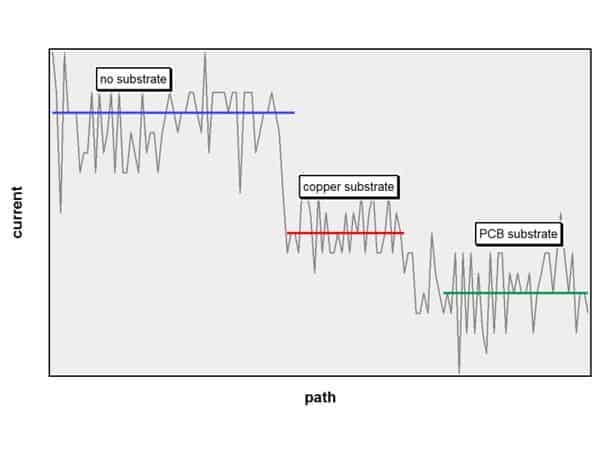

In this measurement, the plasma generator was run over a circuit board at constant speed. As soon as the plasma jet begins to cross the board, the impedance of the electrical environment alters, as it does again when the board’s metalized area changes into unmetalized area.

Changes in working distance

The working distance is one of the parameters which are of particular importance for a consistent interaction between the plasma beam and the surface treated.

The local intensity of the plasma’s effect increases sharply in a nonlinear way with diminished working distance. The jet is maximally focussed near the nozzle exit and has its peak temperature there. Accordingly, there are higher concentrations of non-equilibrium species (ions, radicals and dissociated molecules) inside this hot zone of the gas flow. In order to achieve reproducible surface treatment, the working distance should be kept constant, with variation no higher than about +/- 1mm. Consistent results within this tolerance band are best achieved by keeping a steady traversing speed and choosing a medium working distance of e. g. 15mm.

In one application in vehicle manufacture, for example, the contour where a PUR seal is later applied onto the car body is pre-activated with plasma. The plasma nozzle and sealant nozzle are accordingly mounted onto a multi-axes robot. The relative positioning of the car to the robot can cause faults which may lie outside the tolerance band. To counter this, the process can however be stabilized by adapting the performance parameters of the plasma generator without any mechanical readjustments of the initial positions; alternatively, the robot path can be dynamically reprogrammed. Naturally, the distance information gained from the plasma process can be read to serve as a collision sensor or be logged as a set of QS data.

There is a distinct change in the current and voltage curve when the distance of the nozzle is reduced from 20mm to 4mm. Above 20mm, the curve flattens and approximates totally open jet behavior.

Summary

Our plasmabrush® system, particularly the PS2000 high voltage unit, supplies meaningful digital process data from which valuable process information can be gained based on our years of expertise. In close collaboration with you, we define the operating points for your production steps and provide a working area designed to achieve the desired results. The optimized, cross-platform connectivity of our solution allows for the efficient integration of maintenance and process information into the superordinate host system. Industry 4.0 stands for the interlinking of expert knowledge, production and information technology with the aim of highest possible productivity and reliability.