Accurate surface treatment of electronic devices

Here you can read our test results on the subject: Accurate surface treatment of electronic devices. There are concerns about damage of sensitive components due to different potentials. We started a series of tests in order to analyze whether atmospheric plasma treatment is harmless.

Atmospheric plasma treatment is a common method for fine cleaning and activation

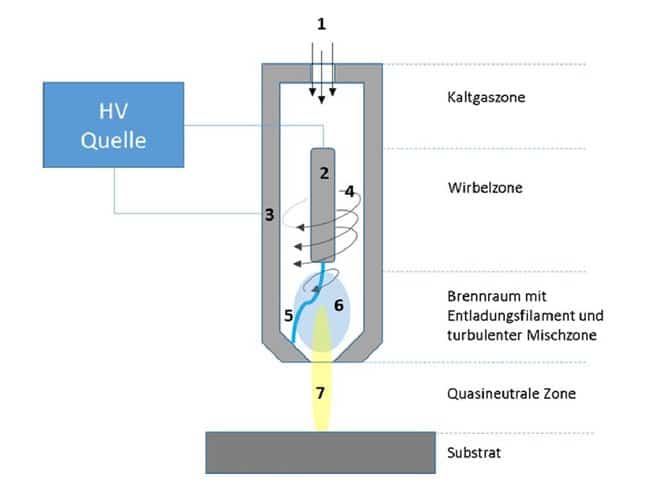

Schematic layout

Atmospheric plasma treatment is a common and established method for fine cleaning and activation of surfaces.

Activating polymers and composites with an atmospheric plasma can be the most efficient method. When using compressed air the process is cost-effective and compatible with nearly every production process. No chemical primers are needed. A functionalization with atmospheric plasma is environmentally friendly and gentle on materials.

Within only one process step, a fine cleaning, a compensation of static surface charges and a functionalization will be done. This will also be reached when treating complete electronic modules. On a circuit board, there is a wide range of materials:

- Thermoplastics

- Metals

- Ceramic surfaces

- Solder resists

- Conductor tracks

- PCB substrates

If a module shall be moulded, an optimization with a dry atmospheric plasma treatment is a highly efficient method, which leads to a homegeneous dispensing quality. Shrinkage cavities will be avoided and protection against moisture penetration will be increased.

Source: www.all-electronics.de